H2Flow Meter

- Thread starter JPMorgan

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flow meters are installed after the filtration system in commercial aquatics applications.

www.blue-white.com

www.blue-white.com

The Flow Meter of Choice for the Aquatics Industry: The F-300 - Blue-White Industries

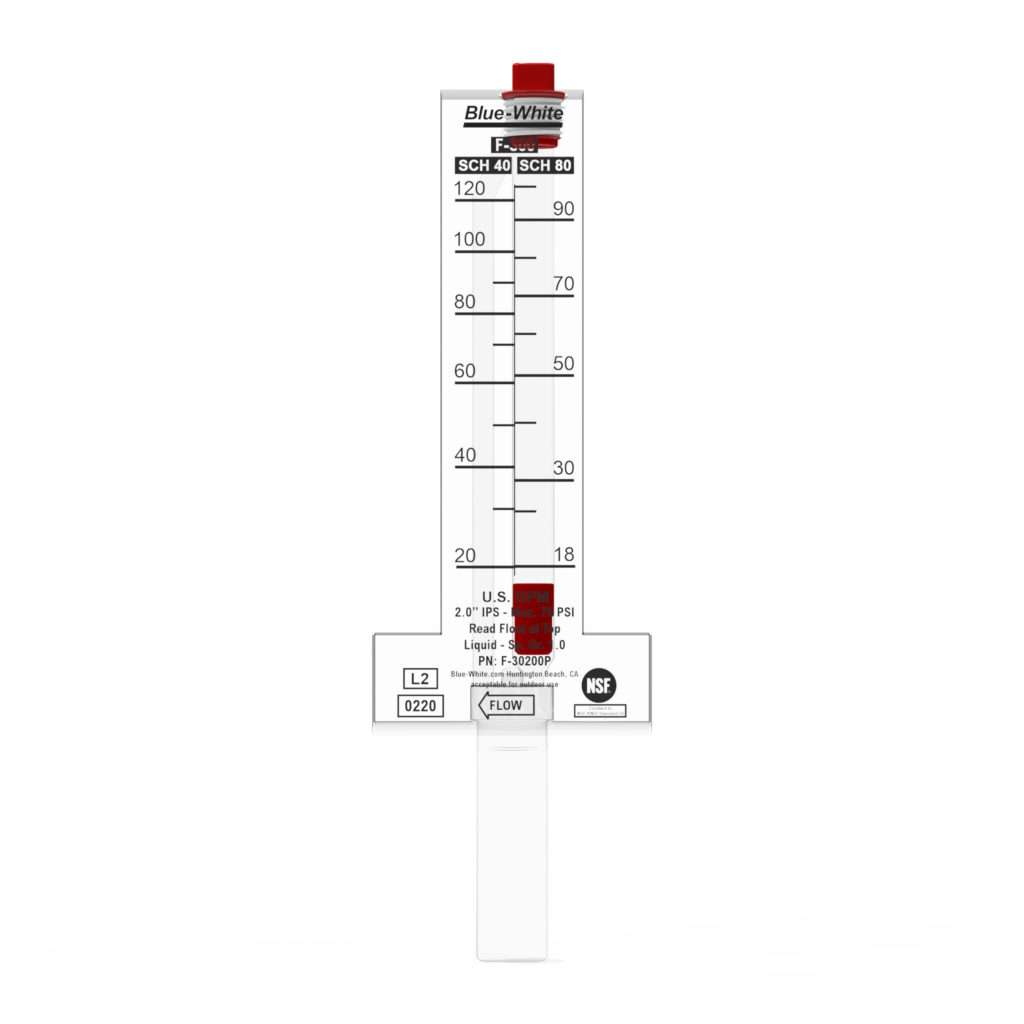

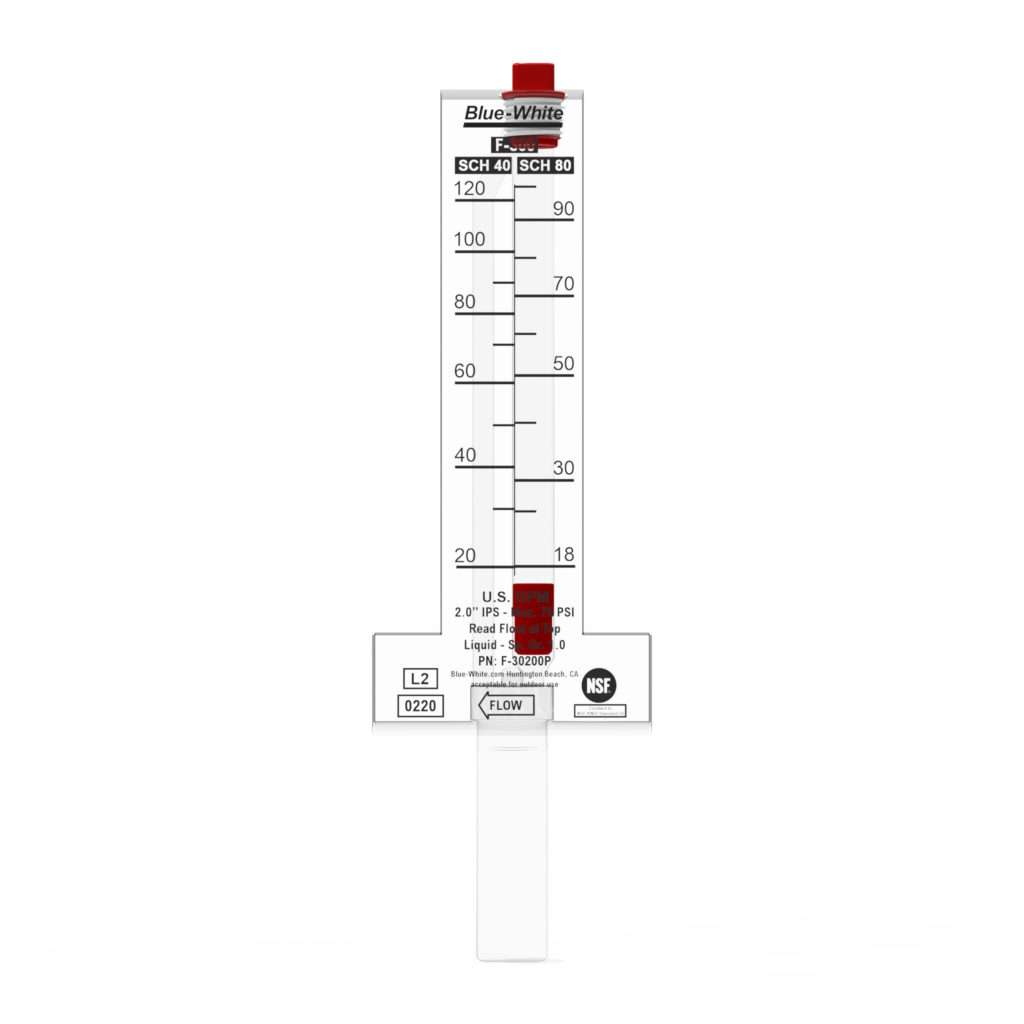

In the early days of the pool industry, King aimed to create vital products for the aquatics field, with the standout being the NSF 50-listed F-300 Series Flow Meter, known for its excellent quality.

Installation: To prevent debris from entering the meter, install the flowmeter downstream from the filter if possible with at least the minimum straight pipe dimensions called for in the above drawing. Drill the pitot tube hole in the top (12 o'clock position) of the horizontal pipe. Carefully remove all burrs.

- May 27, 2021

- 1,253

- Pool Size

- 17000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Been down that road…You end up putting it where the field inspector wants you to for a pass unfortunately. That doesn’t make it correct or even ensure it will function as designed.The engineering specs for our installation say it is to be installed "between the pump and the filter". Is this wrong? The pool company has to follow the engineering specs, though, right? Should we install another flow meter after the filter, as well? If the specs call for a flowmeter "between the pump and filter" that is the one the inspectors are going to read, right?

- May 3, 2007

- 18,052

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

The issue with putting a check valve flow meter between the pump and filter is that debris can get trapped in the flapper and prevent the check valve from fully closing. If that is not important, then I would not worry about it. Also, if the inspectors want it in that location, then that is where it needs to be.

A flow meter should read the same before or after the filter as long as no water is diverted from the path.

A flow meter should read the same before or after the filter as long as no water is diverted from the path.

The BlueWhite pitot tube flow meter is more susceptible to clogging due to the small diameter hole and water path.

Even small debris can clog the flow meter and get stuck between the float and the tubing walls.

I would move the Bluewhite meter to after the filter.

Even small debris can clog the flow meter and get stuck between the float and the tubing walls.

I would move the Bluewhite meter to after the filter.

Did the inspector say that the flow meter had to be between the pump and the filter?

In my opinion, the inspector will not complain about a flow meter after the filter.

Maybe leave the two existing flow meters in place and add one or two more after the filter.

In my opinion, the inspector will not complain about a flow meter after the filter.

Maybe leave the two existing flow meters in place and add one or two more after the filter.

The BlueWhite flow meter was installed by the same company that installed the h2flowmeter only as a way to determine if the h2flowmeter reading was accurate. But, as noted above, it is not installed correctly because it sits right next to the h2flowmeter. I think the best approach is to remove that BW flow meter to a section of piping after the filter where it has the necessary length of pipe before and after the flow meter. That would be a better use of that flow meter. Then we can just plug that hole, apply the new sticker we will receive to the h2flowmeter and... hopefully, we get readings close to 170 gpm. I'll update when we get that done.The BlueWhite pitot tube flow meter is more susceptible to clogging due to the small diameter hole and water path.

Even small debris can clog the flow meter and get stuck between the float and the tubing walls.

I would move the Bluewhite meter to after the filter.

YES!!!Just install the label where the flow rate reads 170 GPM

Apparently the engineer who did our drawings doesn't know this!!!Flow meters are installed after the filtration system in commercial aquatics applications.

Don't really care about the check valve.... just want to get the flow rate we need... hopefully an accurate one. The engineers submit the plans and that State approves the plans, so it appears they want that flow meter between the pump and the filter. I'm not sure where the inspector will want to see it, but if we show him the plans approved by the State, then I don't think he can change it. We will remove the BW flow meter (that currently sits right in front of the h2flowmeter) and put it on a section of pipe after the filter to see what reading we get at that location.The issue with putting a check valve flow meter between the pump and filter is that debris can get trapped in the flapper and prevent the check valve from fully closing. If that is not important, then I would not worry about it. Also, if the inspectors want it in that location, then that is where it needs to be.

A flow meter should read the same before or after the filter as long as no water is diverted from the path.

- May 27, 2021

- 1,253

- Pool Size

- 17000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Ahh yes, you’re in the land of pre certified contractors and state approved plans for any change. Unfortunately living in Peoria for years dealing with that garbage I know the chief engineer will defer to the field agent even when he knows it’s wrong. I was shut down a couple of times in my tenure up north because the field agent wanted it his way……the chief engineer for the state told me just to comply despite the erroneous demands. Do what’s needed to get the permit signed off. Godspeed and good luck lolDon't really care about the check valve.... just want to get the flow rate we need... hopefully an accurate one. The engineers submit the plans and that State approves the plans, so it appears they want that flow meter between the pump and the filter. I'm not sure where the inspector will want to see it, but if we show him the plans approved by the State, then I don't think he can change it. We will remove the BW flow meter (that currently sits right in front of the h2flowmeter) and put it on a section of pipe after the filter to see what reading we get at that location.

The Bluewhite flow meter says 135 gpm.

I don't think that the new sticker will change the reading higher than about 155 gpm.

You have a substantial amount of difference between different methods, which is a good indication that something is off.

This is why I like to have as many different types of measurements as possible.

For example, I have 137 flow meters on my pool and I graph the distribution of readings on a grid to show the bell curve.

Then, I calculate the mean, median and standard deviation.

The standard deviation is 7.37 gpm with a median of 276 gpm.

The accuracy, resolution, precision and repeatability of each meter is also factored in.

So, I never know the exact flow rate but I can tell you the range to a given probability.

For example, if you want to know the flow rate to 68.26% certainty, it is 276 +/- 7.37 gpm.

In other words, about 94 of the flow meters will be within the range of 268.63 to 283.37.

These are the readings from the flow meters.

It is probably more than necessary, but I like to be as sure as possible about the flow.

I don't think that the new sticker will change the reading higher than about 155 gpm.

You have a substantial amount of difference between different methods, which is a good indication that something is off.

This is why I like to have as many different types of measurements as possible.

For example, I have 137 flow meters on my pool and I graph the distribution of readings on a grid to show the bell curve.

Then, I calculate the mean, median and standard deviation.

The standard deviation is 7.37 gpm with a median of 276 gpm.

The accuracy, resolution, precision and repeatability of each meter is also factored in.

So, I never know the exact flow rate but I can tell you the range to a given probability.

For example, if you want to know the flow rate to 68.26% certainty, it is 276 +/- 7.37 gpm.

In other words, about 94 of the flow meters will be within the range of 268.63 to 283.37.

Percentiles

These are the readings from the flow meters.

It is probably more than necessary, but I like to be as sure as possible about the flow.

Attachments

Last edited:

Not if we install the new sticker so it reads 170 gpm (as you suggested)!I don't think that the new sticker will change the reading higher than about 155 gpm.

Bottom line.... the pool has been clean and clear all summer. The new liquid chlorine feeder and new Controller are working to keep the water crystal clear. Whatever we need to do to pass inspection may be the way to go. Hopefully, that doesn't mean a new expensive pump, but if it does... so be it.

Yes indeed. If I knew what I was getting myself into I probably would never have started down this road. What should have been a fairly simple installation of a liquid chlorine feeder and new controller has gotten bogged down over this flow rate issue because of errors and incompetence.Ahh yes, you’re in the land of pre certified contractors and state approved plans for any change. Unfortunately living in Peoria for years dealing with that garbage I know the chief engineer will defer to the field agent even when he knows it’s wrong. I was shut down a couple of times in my tenure up north because the field agent wanted it his way……the chief engineer for the state told me just to comply despite the erroneous demands. Do what’s needed to get the permit signed off. Godspeed and good luck lol

Assuming your readings are 135, 155 and 180, the Sample Standard Deviation is 22.5 and the Population Standard Deviation is 18.4 GPM.

Thanks for all the input and help everyone. I've learned a lot. At this time I'm waiting for the new sticker for the h2flowmeter to arrive in the mail. We will affix that to the flow meter and see what kind of reading we get then. I will have the BW flow meter moved to the return line after the filter as a double check on the flow rate. Hoping that this will get us to where we need to be on the flow.  I will update once these changes have been made.

I will update once these changes have been made.

- May 3, 2007

- 18,052

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

I would not reinstall the BW meter. The error for those types of flow meters is much higher than the FloVis (~5:1) so it is more likely to cause issues with your inspector should it read a significantly different flow rate.We will remove the BW flow meter (that currently sits right in front of the h2flowmeter) and put it on a section of pipe after the filter to see what reading we get at that location.

The BW meter is already reading too low at 135 GPM, so you might have to remove it if it will cause an issue.

The accuracy is listed as +/- 10%, so that is 135 +/- 13.5 or 121.5 to 148.5 GPM.

So, even the best case indicates a low flow condition.

www.blue-white.com

www.blue-white.com

The accuracy is listed as +/- 10%, so that is 135 +/- 13.5 or 121.5 to 148.5 GPM.

So, even the best case indicates a low flow condition.

Full Scale Accuracy:

- +/- 5% (L2 Pipe sizes: 1”, 1.25”, 1.5” and 2”)

- +/- 10% (L3 Pipe sizes: 2.5”, 3”, 4”, 6”, and 8”)

F-300 - Blue-White Industries

F-300 Pitot Tube Acrylic Flow Meter. NSF 50 LISTED 1”, 1.25”, 1.5”, 2” (L2), 2.5”, 3”, 4”, 6”, and 8″ (L3) – Horizontal flow only. Acceptable for outdoor installations (direct sunlight okay)

Last edited:

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.