Since you have at least 3 different ways to calculate the flow, you should log all three over time and then run a statistical analysis on the readings to see how well they match by calculating the standard deviation.

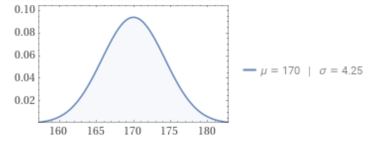

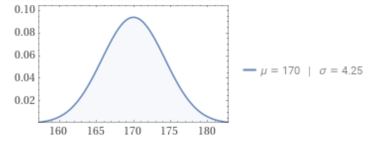

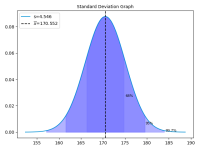

I would suggest a maximum standard deviation of about 4.25 for a mean of 170 GPM.

y =0.0938688 e^(-0.0276817 (x - 170)^2)

www.wolframalpha.com

www.wolframalpha.com

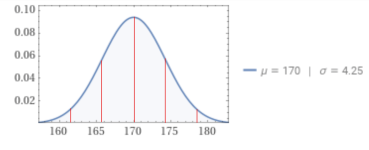

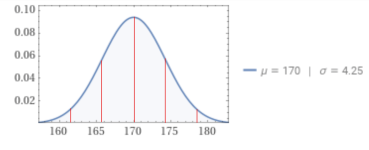

For example, if you have these readings, the standard deviation is 4.55, which is acceptable.

171.139, 168.262, 172.618, 165.91, 164.537, 173.317, 170.344, 172.461, 170.075, 167.758, 163.227, 180.169, 177.31, 174.138, 169.025, 169.166, 175.105, 167.592, 172.223, 172.856, 162.286, 172.131, 167.155, 170.048, 171.169, 174.637, 175.298, 159.688, 175.546, 171.368

www.standarddeviationcalculator.io

www.standarddeviationcalculator.io

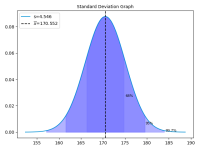

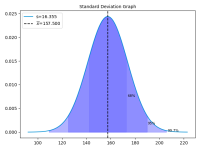

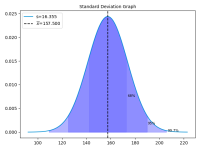

For example, if your readings are 135, 155, 180, 145, 170, 160,

Standard Deviation is 16.355 and the mean is 157.5 GPM.

This would be an unacceptable data set and you would need to address the outlier variables like the 135 GPM reading.

The mean needs to be the minimum required flow rate and the standard deviation should be less than 5 GPM.

I would suggest a maximum standard deviation of about 4.25 for a mean of 170 GPM.

y =0.0938688 e^(-0.0276817 (x - 170)^2)

y=0.0938688 e^(-0.0276817 (x - 170)^2) - Wolfram|Alpha

Wolfram|Alpha brings expert-level knowledge and capabilities to the broadest possible range of people—spanning all professions and education levels.

For example, if you have these readings, the standard deviation is 4.55, which is acceptable.

171.139, 168.262, 172.618, 165.91, 164.537, 173.317, 170.344, 172.461, 170.075, 167.758, 163.227, 180.169, 177.31, 174.138, 169.025, 169.166, 175.105, 167.592, 172.223, 172.856, 162.286, 172.131, 167.155, 170.048, 171.169, 174.637, 175.298, 159.688, 175.546, 171.368

Standard Deviation Calculator - Sample/Population

Use this standard deviation calculator to find the standard deviation, variance, sum, mean, and sum of differences for the sample/population data set.

For example, if your readings are 135, 155, 180, 145, 170, 160,

Standard Deviation is 16.355 and the mean is 157.5 GPM.

This would be an unacceptable data set and you would need to address the outlier variables like the 135 GPM reading.

The mean needs to be the minimum required flow rate and the standard deviation should be less than 5 GPM.