Hey, Guys. I just replaced the 1.5 hp motor, seals, and impeller on my Hayward pump. I noticed that when I open all three suction valves the motor draws high amps. Only when I close off any combination of the three and see some turbulence in the suction filter/screen will the amps drop to 9.2 or 9.3 where it should be. I know electricity extremly well, but I'm at a loss as to why when offering the pump unrestricted suction the amps go up. Any thoughts? Thanks.

High Amps

- Thread starter Airsick

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Current is determined by the load, and the more water the pump can move, the more current it will draw. Dead-heading or restricting the inlet both reduce current draw.

Are you sure you got the right impeller? The impeller size is what limits the load on the motor and the current drawn.

Are you sure you got the right impeller? The impeller size is what limits the load on the motor and the current drawn.

Thanks, guys. We replaced the impeller by using the serial number on the old one. The old motor was 1.5 HP also, and was an exact replacement. Century/AO Smith capacitor inside housing. It began running hot after it had been in service for 2 years.

So if the impeller is capable of moving more water than the motor is designed to handle, by restricting the suction side I'm forcing the motor to work less? I was thinking that by increasing the amount of available suction it would be better.

So if the impeller is capable of moving more water than the motor is designed to handle, by restricting the suction side I'm forcing the motor to work less? I was thinking that by increasing the amount of available suction it would be better.

What is the part number for the impeller?

What is the total hp of the motor?

The total hp of the motor is the hp x the service factor.

What is the model number for the pump?

There should be a silver sticker on the side of the pump (not the motor) with a model number.

Restricting the flow uses less power because the pump is moving less water.

What is the total hp of the motor?

The total hp of the motor is the hp x the service factor.

What is the model number for the pump?

There should be a silver sticker on the side of the pump (not the motor) with a model number.

Restricting the flow uses less power because the pump is moving less water.

The silver sticker reads: SP3010X15AZ

The motor is 1.5hp

Impeller SP3010-C

I think you guys have hit it. The impeller must be too big. That may be why the old motor wore out so fast. When I replaced the old impeller with a new one, even though it was a match (or so said the guy at Pinch A Penny) it's trying to move more water than it's supposed to. I never monitored the amps of the old motor like I've been doing on the new one. I even ordered a panel mounted ammeter!

The motor is 1.5hp

Impeller SP3010-C

I think you guys have hit it. The impeller must be too big. That may be why the old motor wore out so fast. When I replaced the old impeller with a new one, even though it was a match (or so said the guy at Pinch A Penny) it's trying to move more water than it's supposed to. I never monitored the amps of the old motor like I've been doing on the new one. I even ordered a panel mounted ammeter!

For that impeller, the amps at 230 volts should not be above about 9.3 amps.

Check the voltage and the power factor.

Are you sure that the impeller is a SP3010C?

What is the amperage at full flow?

If you don't need that much flow, I would downsize the impeller.

Check the voltage and the power factor.

Are you sure that the impeller is a SP3010C?

What is the amperage at full flow?

If you don't need that much flow, I would downsize the impeller.

Last edited:

If I open all three suction valves (navigator plugged in the side port) the amps go to 10.1. Too much. FLC @ 240 is 9.3, if I remember correctly. When I start closing off some of the valves I can drop the amps down to acceptable, but it sounds like it's cavitating. Am I damaging the system in any way by choking down the suction side? How do I know what part number impeller to buy? This is the impeller I replaced: Hayward SP3010-C, 1 HP full rate / 1.5 HP up rate impeller.

Last edited:

I would drop the impeller down to a SPX3007C or even a SPX3005C.

The SPX3010C should not be drawing that many amps.

Can you show a picture of the impeller and the part number stamped on it?

Does the impeller spin freely or is it binding?

Did you verify that the voltage is good under load?

Did you check the power factor?

Do you have a true RMS meter?

The SPX3010C should not be drawing that many amps.

Can you show a picture of the impeller and the part number stamped on it?

Does the impeller spin freely or is it binding?

Did you verify that the voltage is good under load?

Did you check the power factor?

Do you have a true RMS meter?

Last edited:

This is the impeller I took off and had Pinch a Penny match. I don't have a pic of the one I installed. Yes, I have a good meter and the voltage is 239.9 under load. There's no binding. I think you're right that for some reason this setup has a mismatched motor and impeller. If I change the impeller do I have to change other parts, too? The reason I had to change the impeller was I put the shaft seal on backwards and had a meltdown. I know electricity, not plumbing!

Last edited:

That impeller looks like it was grinding.

What diffuser and impeller ring do you have?

If the impeller is definitely not binding, then I think that you probably have a bigger impeller than the original impeller.

I would downsize the impeller to the 07 or 05 depending on how much flow you need.

What diffuser and impeller ring do you have?

If the impeller is definitely not binding, then I think that you probably have a bigger impeller than the original impeller.

I would downsize the impeller to the 07 or 05 depending on how much flow you need.

Last edited:

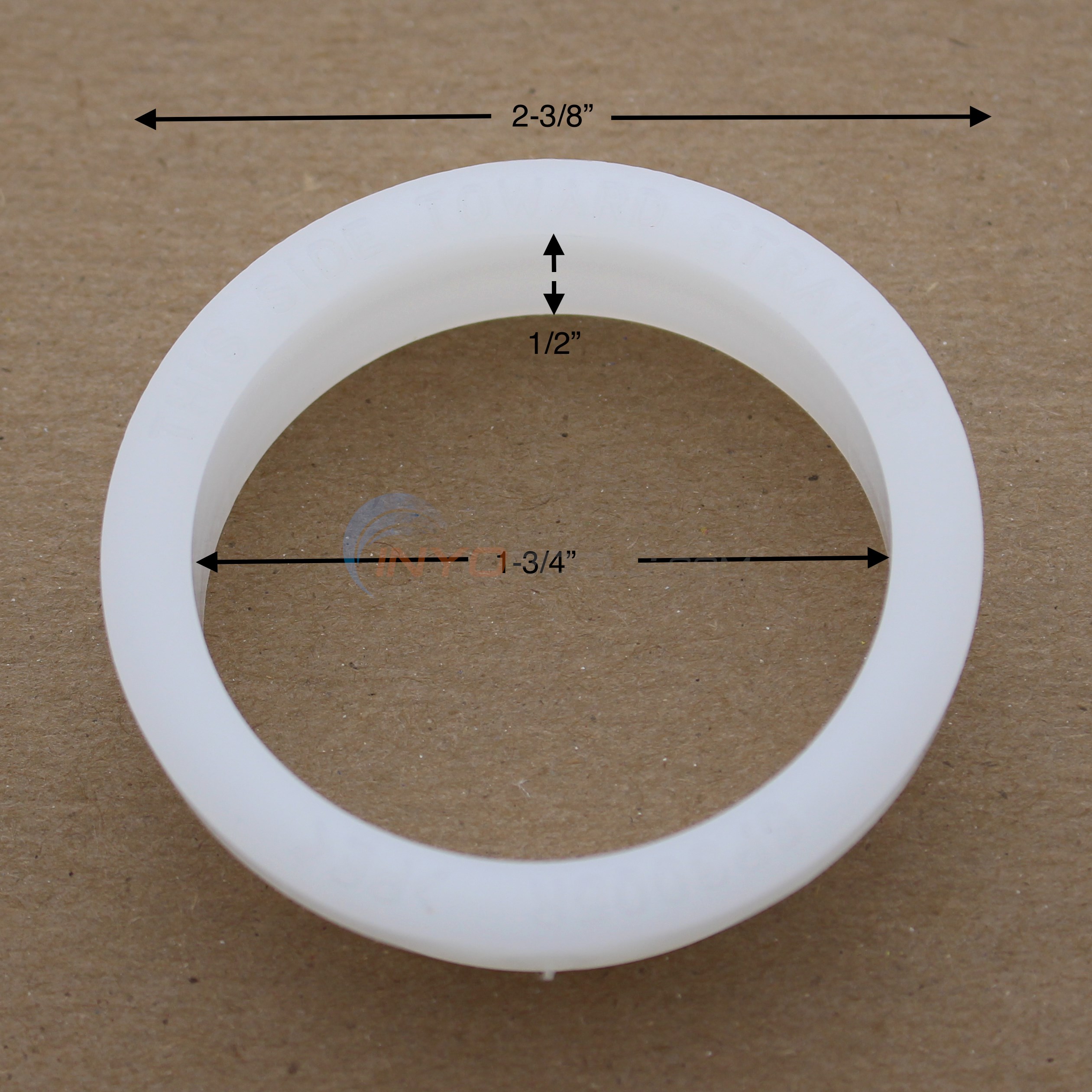

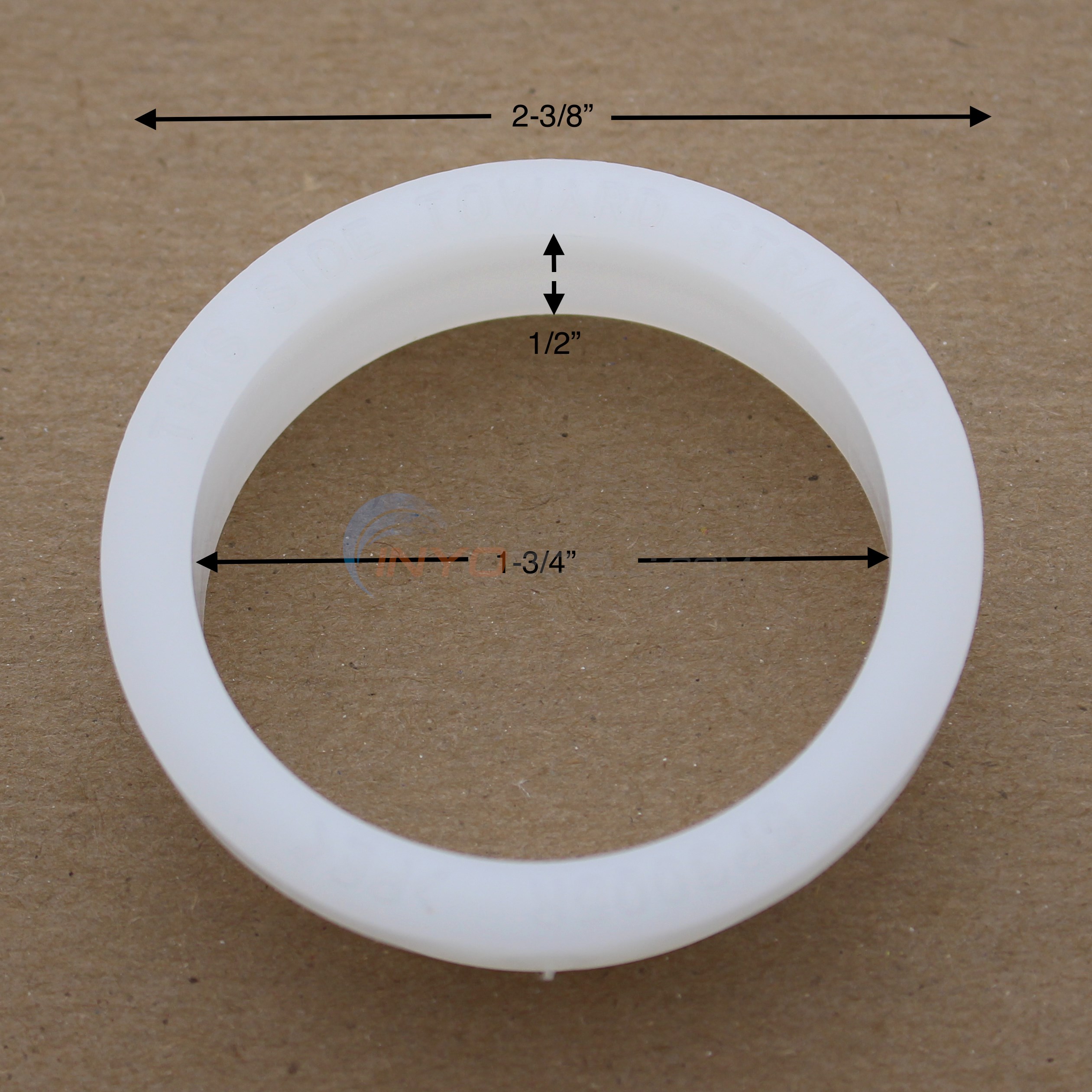

Do you have this impeller ring? SPX3005R.

Can you feel the impeller spin easily?

If the impeller spins with no binding, it's probably a SPX3015C or a SPX3016C.

Did you check the part number for the impeller before you installed it?

Did you install the SPX1600R diffuser O-ring?

Can you feel the impeller spin easily?

If the impeller spins with no binding, it's probably a SPX3015C or a SPX3016C.

Did you check the part number for the impeller before you installed it?

Did you install the SPX1600R diffuser O-ring?

I just watched the guy on the counter put the pump back together. I had taken the old motor off to bench test it because I could smell it running hot. It ran ok, but then I put the shaft seal on backwards and melted the parts. I took the pump (sans motor) to PAP and had them rebuild the pump. Bolted the old motor on and it ran hot for a couple of days then started tripping the thermal overload. I ordered a replacement motor and put it on the newly rebuilt pump. That's when I started checking amps. I'll bet the old motor was running high amps, too, I just never checked it under load. Anyway, when I open the suction valve(s) all the way the pump runs quieter with no cavitation, but as we now know, draws too much water and overworks. To keep the amps down I throttle down the suction and have to listen to that cavitation-like sound. I'd much rather just have a nice humm, so I will change out the impeller.

To answer your questions, I'd have to find my receipt to see exaclty what parts I had installed.

To answer your questions, I'd have to find my receipt to see exaclty what parts I had installed.

How did they do anything without the motor?I took the pump (sans motor) to PAP and had them rebuild the pump.

Can you reach into the diffuser hole from the inside of the pump with the basket out to feel if the impeller is binding? Make sure that the power is off at the breaker so that the pump does not turn on.

Or, you can access the back of the shaft to feel if it spins freely.

In any case, you should plan to take it apart and redo everything with the SPX3007C impeller, a new seal, a new diffuser gasket and a new impeller ring.

I didn't want to carry that heavy thing all the way to the counter. The motor is only 4 bolts.

Will take your advise. Many thanks.

Will take your advise. Many thanks.

You can't install the impeller until the motor is mounted to the seal plate.

What else is there to do?

What else is there to do?

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.