- Mar 4, 2018

- 6

- Pool Size

- 25000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite Pro (T-15)

Hey pool friends -

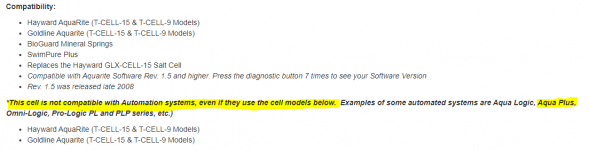

Hayward Aqua Plus automation system with a T-CELL-15 that finally rusted on me and is leaking; I'm looking at wiring diagrams, troubleshooting guides and pictures online; all my research for the T-CELL-15 tells me the yellow and orange wires (going to the temp sensor) are not used. Most pictures I've come across show them cut off, yet mine seem to be intact and part of the sensor.

Can anyone tell me what these do?

I ask because, in my efforts to get a replacement, I tried a generic cell that only has the 6 wires in the molex (pictured below), but I immediately get a 'sensor fault' error when the chlorinator turns on; this makes me believe all 8 wires are required. Is this just for the automation systems maybe?

Generic Cell Molex (only 6 connectors)

OEM/Original Hayward Molex (has 10 connectors for all 8 wires)

Thanks in advance for any info anyone can provide.

Hayward Aqua Plus automation system with a T-CELL-15 that finally rusted on me and is leaking; I'm looking at wiring diagrams, troubleshooting guides and pictures online; all my research for the T-CELL-15 tells me the yellow and orange wires (going to the temp sensor) are not used. Most pictures I've come across show them cut off, yet mine seem to be intact and part of the sensor.

Can anyone tell me what these do?

I ask because, in my efforts to get a replacement, I tried a generic cell that only has the 6 wires in the molex (pictured below), but I immediately get a 'sensor fault' error when the chlorinator turns on; this makes me believe all 8 wires are required. Is this just for the automation systems maybe?

Generic Cell Molex (only 6 connectors)

OEM/Original Hayward Molex (has 10 connectors for all 8 wires)

Thanks in advance for any info anyone can provide.

Last edited: