For a rectified system, when an AC supply voltage is placed across the two electrodes during the first half of the AC cycle, the flame rod is positive and the grounding area is negative (Figure 9 A).

The positively charged ions collect on the negative charged grounding area.

Since the grounding area is very large, it holds many ions.

The positively charged ions pull a high stream of electrons into the flame, more than if the grounding area was the same size as the flame rod.

This results in a high current flowing from the grounding area to the flame rod during the first half cycle of the AC supply voltage (Figure 9 C).

During the second half cycle, the reverse process takes place (Figure9 B).

However, the capacity of the flame rod to hold ions is less than the grounding area and the resulting flame current is smaller (Figure 9C).

Since the current in one direction is so much larger than the current in the other direction, the resultant current is, effectively, a pulsating direct current (Figure 9C).

The flame signal should be steady when measured with a DC microammeter (μA).

opentextbc.ca

The Process of Flame Rectification

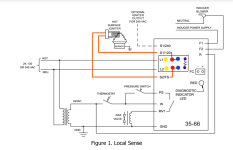

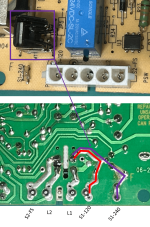

The board puts out 40VAC to 120VAC (manufacturer dependent) on the flame rod wire.

The flame rod is always energized when the furnace board is powered.

Honeywell Smartvalves are ~170 to 180VAC.

Honeywell S8610U3009 are ~170VAC that will produce ~1 to 2 µADC.

The fuel ignites and flame is present.

The 40VAC to 120VAC passes current through the flame to complete the circuit by grounding to the burners

This "grounding" of the circuit makes a good ground essential!

The ions in the flame only allow half (+ ions) of the AC sine wave to pass through the flame.

This is called "Rectification".

This process is the changing of the AC signal into a rectified DC signal.

Once the flame is present and this rectification circuit completes, then power flows through the circuit and is measured in Microamps DC (µADC).

The furnace board will constantly monitor this µADC signal to verify a safe operation during the heating run cycle.

A typical flame rod circuit will carry between 1 to 6 µADC

Most furnace boards need a minimum of 0.5 µADC for the furnace to stay running.