I'm in the midst of design and the least obtrusive pool equipment location is 100 feet away from the spa, 90 from vac line and 80 feet from the drain. The alternative is that I have the equipment behind the end of the pool and knock about 60 feet off of each of those numbers. I could put the in-floor cleaning rotating box substantially closer (50' feet closer) if that helps so that all of those small runs into the in-floor heads are only 30 to 40 feet if that helps anything.

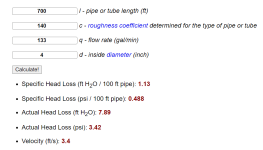

Are there concerns with these 100/90/80 feet long distances? It would come with the same number of 45's and elbows as short run distance I imagine.

What am I giving up (if anything beyond additional plumbing costs) by having longer runs?

Exact equipment isn't specified yet but it will be variable speed and a 2hp blower.

Comments or suggestions?

Are there concerns with these 100/90/80 feet long distances? It would come with the same number of 45's and elbows as short run distance I imagine.

What am I giving up (if anything beyond additional plumbing costs) by having longer runs?

Exact equipment isn't specified yet but it will be variable speed and a 2hp blower.

Comments or suggestions?