I have Hayward H400FDP heater that had some problems after a recent storm. After finding a shorted out fuse board, I replaced the fuse board as well as the control board that included a new blower vac switch in the kit and the heater fired up and appeared to working. After about 10 minutes, it shut down. I removed the side panel and restarted, and could see that I had a good flame and the water temp increased about 10 degrees, and the heater shut down again within about 10 minutes. I disassembled and cleaned the DE filter, even though it didn't look too bad. I'm not getting any error codes, so really don't know which way to go. Faulty flame sensor? Not sure if that's the case since the igniter seems to be working just fine and I have a nice flame. Something is telling the heater to shut down but I'm at a loss.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jul 21, 2013

- 64,901

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Welcome to TFP.

The first step is to clean the flame sensor. Having a nice flame does not mean it is being sensed.

The flame sensor should be cleaned with steel wool or a small steel/diamond file because cleaning with sandpaper or emery cloth can leave a residue impeding conductance. On the other side (ground side), all surfaces from the burner back to the case ground must be clean, bare metal (as the flame signal is sensed through the flame). This includes the burners and burner slots, which can be cleaned with a wire brush, and any other metal-to-metal surfaces back to the case ground that may have lost conductance due to dirt/corrosion/oxidation. This would include orifices ( if the burners are hung directly on the orifices ), burner brackets, and any other metal-to-metal breaks between the burners and the case ground.

www.troublefreepool.com

www.troublefreepool.com

The first step is to clean the flame sensor. Having a nice flame does not mean it is being sensed.

The flame sensor should be cleaned with steel wool or a small steel/diamond file because cleaning with sandpaper or emery cloth can leave a residue impeding conductance. On the other side (ground side), all surfaces from the burner back to the case ground must be clean, bare metal (as the flame signal is sensed through the flame). This includes the burners and burner slots, which can be cleaned with a wire brush, and any other metal-to-metal surfaces back to the case ground that may have lost conductance due to dirt/corrosion/oxidation. This would include orifices ( if the burners are hung directly on the orifices ), burner brackets, and any other metal-to-metal breaks between the burners and the case ground.

Hayward H-Series Heaters - Further Reading

Thanks. I actually have a flame sensor on order, which should be arriving today. Unfortunately, its been raining. Soon as the weather clears I'll give this a try and report back. I'm a few weeks past rotator cuff surgery and looking forward to soaking in a hot spa after physical therapy. Would a faulty flame sensor allow the heater to run for 10 minutes (in my case) or any length of time before shutting the heater down? My understanding is the sensor reacts fairly quickly.

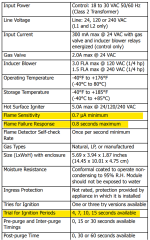

Check the voltage going to the flame sense rod.

You should measure about 90 volts AC from line to ground.

Check the current (DC microamps) going through the flame sense wire.

You should see about 2 to 5 DC microamps for normal operation.

0.7 to 1.0 µA (Microamps) is a typical minimum range.

You should measure about 90 volts AC from line to ground.

Check the current (DC microamps) going through the flame sense wire.

You should see about 2 to 5 DC microamps for normal operation.

0.7 to 1.0 µA (Microamps) is a typical minimum range.

Last edited:

It can if the Flame Current is weak and close to the shutoff level.Would a faulty flame sensor allow the heater to run for 10 minutes (in my case) or any length of time before shutting the heater down?

Loss of Flame Rectification usually responds in about 0.8 seconds by closing the gas valve.My understanding is the sensor reacts fairly quickly.

Typically, the Trial For Ignition is about 4 to 7 seconds.

Trial for Ignition is when the gas valve is opened and the board is looking for good flame rectification of at least 0.7 microamp DC of flame current.

If the flame current is not at least 0.7 microamp within 7 seconds, the board closes the gas valve.

You might get 0.8 microamp DC and then it falls below 0.8 microamp and the board shuts the gas valve.

Flame Sensitivity 0.7 µA minimum.

Note that different control boards use different flame current minimums and different trial for ignition periods.

Numbers used are from Fenwal SERIES 35-66 ICM (Ignition Control Module) and Hayward might use other numbers, but they will be similar.

Some ICMs have Flame current test points that you can use, especially if the ignitor is also the flame sensor (Called Local Sense).

If you have a separate flame sense rod, you test flame current by putting the meter inline and measuring DC microamps.

Note: The HDF400 GAS HEATER uses a 4 second trial for ignition.

Attachments

Last edited:

UHS Sequence of Operation: Normal

The control continually compares the set temp to the actual water temp.

When the water temp is 1º below the set point the following sequence starts:

1. The control checks for open blower vacuum switch.

2. Blower starts pre-purge cycle as the ignitor heats up (20 Sec).

3. The control checks for a closed blower vacuum switch.

4. At proper ignitor temp, a 4 second trial begins. Gas valve opens and monitors flame sense.

The blower will turn off for one second.

The ignitor is de-energized at flame sense or at completion of 4 sec trial.

If the flame is sensed, The blower vacuum switch, control loop, temp sensor & flame sensor are constantly monitored during call for heat.

5. When set temp is reached, the control ends the call for heat, the gas valve is de-energized, and the flame is extinguished.

6. The blower will operate for a 30 second post purge.

________________________________________________________________________

If trial fails:

1. Gas valve de-energizes (for 30 second, blower post purge).

2. Starts over at #2 of heating mode sequence.

3. Retries 3 times until lockout (IF code).

4. Waits 60 minutes then retries 3 more times.

5. Will continue to retry every 60 minutes, until demand for heat is stopped.

The control continually compares the set temp to the actual water temp.

When the water temp is 1º below the set point the following sequence starts:

1. The control checks for open blower vacuum switch.

2. Blower starts pre-purge cycle as the ignitor heats up (20 Sec).

3. The control checks for a closed blower vacuum switch.

4. At proper ignitor temp, a 4 second trial begins. Gas valve opens and monitors flame sense.

The blower will turn off for one second.

The ignitor is de-energized at flame sense or at completion of 4 sec trial.

If the flame is sensed, The blower vacuum switch, control loop, temp sensor & flame sensor are constantly monitored during call for heat.

5. When set temp is reached, the control ends the call for heat, the gas valve is de-energized, and the flame is extinguished.

6. The blower will operate for a 30 second post purge.

________________________________________________________________________

If trial fails:

1. Gas valve de-energizes (for 30 second, blower post purge).

2. Starts over at #2 of heating mode sequence.

3. Retries 3 times until lockout (IF code).

4. Waits 60 minutes then retries 3 more times.

5. Will continue to retry every 60 minutes, until demand for heat is stopped.

Attachments

Last edited:

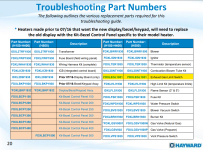

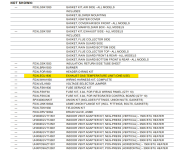

IGNITOR & FLAME SENSOR HDXFIGFS001. HDXFIGFS002

Hayward Ignition Kit & Flame Sensor For HDF400 Heaters | HDXFIGFS001 | HDXFIGFS002.

hayward.com

hayward.com

Hayward Ignition Kit & Flame Sensor For HDF400 Heaters | HDXFIGFS001 | HDXFIGFS002.

KIT-IGN & FLAME SENSOR,HDF (Open Line)

Attachments

Last edited:

If the heater shuts off due to an error, you should get an error code.

Is the water temperature displayed going up when the heater starts?

Can you show pictures of the System?

Is the water temperature displayed going up when the heater starts?

Can you show pictures of the System?

TFP is a registered 501(c)3 non-profit that is maintained by user donations.

The people who answer questions are volunteers.

If you find the site to be a good resource, please consider making a donation to help support the site.

Thanks.

www.troublefreepool.com

www.troublefreepool.com

The people who answer questions are volunteers.

If you find the site to be a good resource, please consider making a donation to help support the site.

Thanks.

Become a TFP Supporter

Help Support TFP Trouble Free Pool is run by a dedicated group of volunteers that … Read more…

I installed the new flame sensor and double checked the grounds...everything looked good. Set the spa temp to 95 degrees, and fired up the heater. Heater cut out again after 10 minutes or so, and zero error codes. When I have some more time, I'll complete the electrical checks as outlined in the above recommendations. Just one odd thing. On my heater, there' a sensor of some type on the face of the heat exchanger, with the wires going to the high limit switches. What's odd is the sensor (or whatever it is) doesn't appear in the heater's exploded parts view in my manual.

No error code. I set the spa temp on the remote controller to 95 degrees; current water temp is 59 degrees and is also displayed on the heater's panel. Once the heater fires up, the water temp as indicated on the remote and heater panels climbs to about 68 degrees or so and then the heater shuts down (usually in about 10 minutes). I replaced the fuse board, control board, and blower vacuum switch about a week ago (all were Hayward OEM parts). Not sure if there's a faulty temp switch somewhere that's causing the shutdown, but then you'd expect to see an error code. I can get some pics once I get some more free time.If the heater shuts off due to an error, you should get an error code.

Is the water temperature displayed going up when the heater starts?

Can you show pictures of the System?

Exhaust gas temperature limit:

The exhaust gas temperature limit monitors the flue gas temperature above the heat exchanger and trips if temperature rises high enough to indicate that the heat exchanger has been damaged and is no longer transferring heat to the pool water effectively.

If this limit trips, effort must be made to rectify the situation that has damaged the heat exchanger.

This is generally due to low water flow, poor water chemistry, or a combination of these and other factors.

Replace the limit as well as the heat exchanger before operating the unit again.

Running the unit without replacing the heat exchanger after this limit trips could damage the entire unit and will not be covered by Hayward’s warranty.

To replace the exhaust gas temperature limit:

1. Turn pump, gas supply, and heater power “OFF”.

2. Remove the upper end cap on the header side of the unit (see Figure 8).

3. Unplug the two wires from the exhaust gas temperature limit located in the flue collector panel above the middle of the header.

4. Unscrew the (2) screws securing the limit to the panel and remove the limit and gasket.

5. Place the new limit and gasket in place and reverse the above steps to complete the procedure.

The exhaust gas temperature limit monitors the flue gas temperature above the heat exchanger and trips if temperature rises high enough to indicate that the heat exchanger has been damaged and is no longer transferring heat to the pool water effectively.

If this limit trips, effort must be made to rectify the situation that has damaged the heat exchanger.

This is generally due to low water flow, poor water chemistry, or a combination of these and other factors.

Replace the limit as well as the heat exchanger before operating the unit again.

Running the unit without replacing the heat exchanger after this limit trips could damage the entire unit and will not be covered by Hayward’s warranty.

To replace the exhaust gas temperature limit:

1. Turn pump, gas supply, and heater power “OFF”.

2. Remove the upper end cap on the header side of the unit (see Figure 8).

3. Unplug the two wires from the exhaust gas temperature limit located in the flue collector panel above the middle of the header.

4. Unscrew the (2) screws securing the limit to the panel and remove the limit and gasket.

5. Place the new limit and gasket in place and reverse the above steps to complete the procedure.

Haven't been able to get much accomplished due to the heavy winds we've been having. I did replace the flame sensor, with the same end result. I did have a chance to remove the heat exchanger cover for an inspection...found a tiny bit of debris (leaves, insects) and vacuumed them out. Overall, the HX looked good, fins were clean, no soot or anything. The exhaust gas temp limit was within electrical specs. Hopefully this weekend I can get back into it.