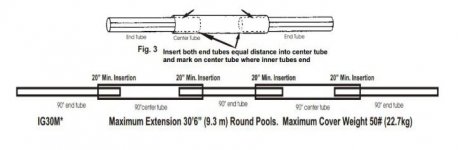

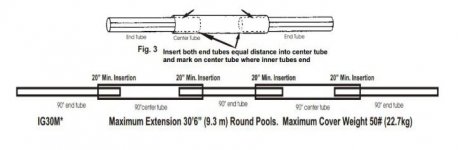

I have a 30' round AG and I am looking to add some poles from a reel tube kit to lengthen a 21' reel someone gave me so I can accommodate a 30' solar cover. Has anyone ever tried this? At first I thought that the more tubes and connections points I had would mean less stability, but after looking at the assembly instructions for the one brand of reels I've found that actually make a 30' span, I see that their kit uses 5 poles instead of the normal 3 for all other sizes. I found a discounted 3 pole kit that matches mine for just $65 so I'm just wondering if I couldn't just use that extra tube kit with the 21' reel I already have to lengthen the span. My 21' reel has three 8' tubes (3" diameter) that connect together, just like the one shown on top in the picture below. By using just 2 more tubes from another tube kit, I should be able to assemble the reel just like that shown in the second picture below to give me the extra 10' I need. This should also leave me plenty of room to fit the tubes far enough inside each other at the joints to make them strong and stable, right? (Maybe even more so, since their instructions show their kit only has 7.5' poles.) This all makes perfect sense to me IN THEORY, but I'm super curious to see if there are any other folks who have attempted this, or who may be more mechanically inclined, and could tell me if my idea may work IN PRACTICE, rather than just on paper.