The pool pump outlet should be

single use with

GFCI, a

locking plug and an

"In-Use" cover.

You also need a maintenance disconnect (Switch) for the pump to allow someone to turn the pump off in an emergency.

The switch needs to be outdoor rated (weatherproof).

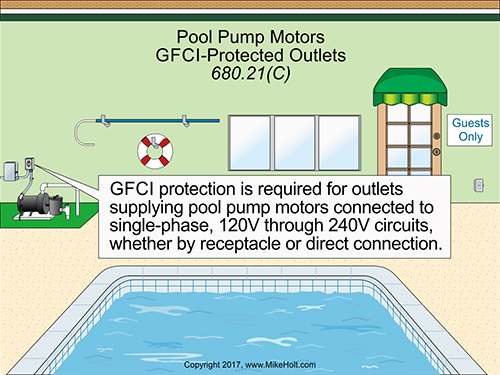

A

separate GFCI protected convenience receptacle is needed 6’ to 20’ from the pool.

The Pump is required to be "Listed" by a NRTL like UL or other qualified testing laboratory.

5. Electrical Requirements.

•

Convenience receptacle is needed 6’ to 20’ from the pool GFCI protected.

•

Pool pump receptacle needs to be single GFCI protected with an in use cover (5’ away from pool).

• Conduit for the pool pump shall be minimum cover of 12” when the circuit is GFCI protected before the conduit enters the ground.

• Pool pump receptacle shall be mounted on a post usually 4’ x 4’ pressure treated.

• Pool pump receptacle feed wires shall be individual conductors in conduit PVC or metal.

• Pool motor needs to be bonded to the pool with a #8 solid copper wire.

• If the ladder is metal it must also be bonded to the pool.

• All metal within 5’ of inside wall of pool shall be bonded to the pool with #8 solid copper.

• Bonding connectors shall be stainless steel, brass, copper or copper alloy.

Swimming Pool Electrician: KB Electric LLC is Montomgery County, PA's #1 swimming pool electrician serving all of Southeastern, PA.

kbelectricpa.com

Some Electrical requirements for outdoor above ground swimming pools. (From the NEC 2017 edition)

Note: All applicable NEC requirements apply, not just Article 680.

1. No aerial wires within 10 feet of the water’s edge.

2.

Electrical equipment must be listed.

3. Grounding and bonding terminals are to be identified for wet and corrosive environments.

4. Underground conduit to be buried a minimum of 18 inches.

5. Pool equipment other than lighting to have a

maintenance disconnect at least 5 feet horizontally from the inside pool wall.

6. Outdoor receptacles must be GFCI protected.

7. Pool pump motors must be GFCI protected, the receptacle can be mounted on a pressure treated 4 x 4, with the receptacle at least 6 feet from the inside wall of the pool.

8. At least one receptacle must be located at least 6 feet and not more than 20 feet from the inside

wall of the pool.

9. Perimeter bonding is required for all surfaces surrounding an above ground pool, including unpaved lawn.

A solid #8 AWG copper wire must be installed 4-6 inches below grade at 18-24 inches from the pool perimeter.

The conductor is to be bonded to the pool at four equally spaced points and all metal items (ladder, fencing, pool frame etc.) within 5 feet to be bonded to the #8 copper wire.

10. The pool water must be bonded to the #8 copper conductor with a fitting installed in the filtration system or other approved device.

11. UF cable is not permitted near pool water or chemicals.

PVC conduit and wet location rated conductors with an insulated equipment grounding conductor are code compliant.

12. Indoor installations may use any NEC Chapter 3 wiring method.

Where subject to pool water and chemicals an insulated equipment grounding conductor is required.