Hello,

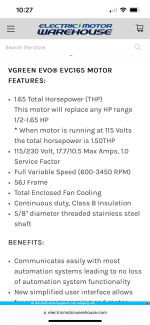

I have a pump motor that is new as of last year (Vgreen EVO EVC165) set up as 115V. It's on a 20amp dedicated circuit/breaker with a 20amp GFCI outdoor rated outlet. There is a hardwired Intermatic timer in the mix as well. I noticed yesterday when I went to unplug it that the plug itself was quite hot. There also appears to be a little char or corrosion on the prongs which is obviously concerning.

What would cause this? I have a hard time believing that the pump motor would be failing already and pulling too much amperage. Is it possibly a wiring problem on the house side? Should I replace the outlet itself (only a few years old)?

Thanks!

I have a pump motor that is new as of last year (Vgreen EVO EVC165) set up as 115V. It's on a 20amp dedicated circuit/breaker with a 20amp GFCI outdoor rated outlet. There is a hardwired Intermatic timer in the mix as well. I noticed yesterday when I went to unplug it that the plug itself was quite hot. There also appears to be a little char or corrosion on the prongs which is obviously concerning.

What would cause this? I have a hard time believing that the pump motor would be failing already and pulling too much amperage. Is it possibly a wiring problem on the house side? Should I replace the outlet itself (only a few years old)?

Thanks!