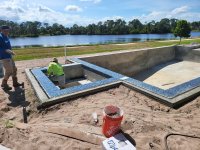

05 May Update - More progress, still a lot left to finish tile

Got most of the beam level prep done yesterday and actually got about half of the edge tile done. This is taking longer than I thought it would but it's also very important to get it right. Based on progress so far I'd now say we have 5 working days left if the sub can field two mini-crews for that time. In the current market for good craft that's a big question mark. We had two crews but I'm pretty sure they were working Saturday to bring in extra money. May be committed during the week to other jobs. This is just the way today's market is. I try to help compete by making this a good place to work. We have covered patio for lunch breaks and a clean restroom for all to use (our cabana bath). We also provide lunch on Friday's and Saturdays. This is not typical at all for most builders but it's an easy calculation for me. $100/day extra to get 2 crews for a day. Based on direct hire of the crews, total cost for tile part of this job was marked up almost 2x by builders that quoted my work and probably worth it if they actually do the job... sadly most of them that I've seen don't.

Even though I've got some really good quality craft prepping and setting tile I find quality control is very important. Probably because the gutter drain concept is so different for this pool. The zero edge I'm doing isn't like any other design I've seen so I go out with the zip level to check pool inside edge and slope of outside edge frequently. They clearly get the inside edge has to be as close as possible to the same all around the pool. But they have struggled with the concept the outside edge has to slope down toward the gutter. If it's not done right this pool will never be able to put enough water over the long infinity wall for "infinity mode". When I close the gutter valves water will just pour all over the deck... Robin would not like that! After a few checks and interventions both crews finally got this.

Safety is an on-going concern for me. Yesterday, I had to stop work for a moment. A young laborer was doing some minor concrete grinding with no eye protection. When I explained I care about his eyes he seemed shocked as did his boss. This is so typical for residential construction. What's acceptable would be an immediate termination on an industrial job. I know they have insurance and liability coverage but I just don't want anybody hurt on my job. This is one of an owner builder's primary responsibilities in my mind.

Tile was the primary focus yesterday but I also had my excavation sub on site to do some fill and compact work plus preliminary grading. Also removed the final 3 loads of dirt. So it's still a mess out back but looking like it could be a real backyard with a pool again someday.

@kimkats has done a great job in her many posts to warn prospective OP's about the mess and boy is she right! View out the back looked like I was building a house again.

In the "when it rains, it pours" pours category. With all this work going on I didn't really have time for distractions. But that's exactly what I got when all the water in the house started smelling like a sewer. Turns out my sulfur removal aerated catylitic carbon filter completely stopped working and I had over 2 ppm sulfide... my wife can reliably detect 85 ppb. That will have to be addressed today when I won't have any PB work going on. I have to say Robin has been very patient with me on this... I think she's actually starting to feel sorry for me that this job has me working pretty hard.

Photo's from yesterday below.

Chris