- Jul 6, 2020

- 19

- Pool Size

- 15000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

How many salt pool owners check if their flow switch is working? If it registers “flow” when the pump is not running, the system may activate SWG when it should be off. The plumbing could have a concentrated buildup of gases, a serious safety issue. Plus it could damage the expensive salt cell.

I’ve probably never paid any attention. But recently when the main pump motor was off, I happened to cycle through my controller settings. I saw a display of “flow” when, of course, there was no water flow (a “fault” that did not shut the system down).

For the record, my 10-year old salt pool is controlled by Hayward ProLogic PL-PS4. So, I don’t know if other models or manufactures have the same setup or even if my unit was setup correctly. Who knows... my flow switch may have failed years ago!!

Here’s the rest of my story leading to the “enigma”:

Intending to bench test the electrical functionality of my OEM flow switch, I accidentally broke off the wire flush at top of the switch assembly… so couldn’t attach a meter.... no test.

I shorted together the 2 broken lead wires (makes the system run and produces chlorine as usual) while I went searching for a new flow switch.

Hayward OEM at Leslie’s for $249.99 or Amazon knockoff for $16.66? Reviews are good and bad for dozens of switches across many price points. Hayward says that only their OEM switch will work. Others claim that the cheap ones last for years. Amazon indicates that these switches are often returned as non-functional even when they subsequently test OK.

I did a minor exploration about reed switches and concluded that they generally are quite reliable. I surmised that the flow sensor issues may be more attributable to incorrect installations, plumbing obstructions, water flow, or mechanical problems.

Next, I plugged into my ProLogic a new (low-priced) flow switch; it didn’t work!

It’s just a switch, right? I did a bench test for continuity between the phone connector plug 2 center contacts. My multi-meter showed... open / then closed... as I squeezed the switch paddle back and forth. (As the magnet on the paddle nears the internal reed switch, it closes to complete the circuit; then it opens when the paddle springs back into its relaxed position.)

The switch works. But not in my system. What’s different? The wires? The plug??

It’s a phone plug…. probably RJ11-6P4C or RJ11-6P2C (6positions/4 contacts or 6positions/2contacts).

My old broken OEM assembly has 2 wires and its modular connector has just 2 contacts centrally located in the RJ11 plug.

Conversely, my new switch assembly has 4 wires and 4 contacts with only the 2 center wires connected to the flow switch … [Why do they use 15 feet of 4 wires when only 2 wires are needed!??]

Could this possibly make a difference? Both plugs have the same physical interface and both snap into the same female socket on the controller board.

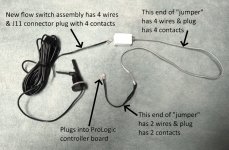

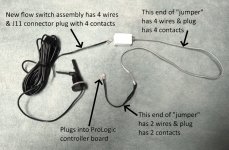

For a test, I created a “jumper” cable by splicing a 2-wire cable to a 4-wire cable (using just the 2 center wires). The 2-contact end plugs into the ProLogic and the 4-wire flow switch plugs into the 4-contact end of the “jumper”. See attached photo of the work-around “jumper”.

My system is currently 100% functional for several days now.

Why this works baffles me! It’s my enigma! It doesn’t make any sense! Can anybody explain this?

In summary:

I’ve probably never paid any attention. But recently when the main pump motor was off, I happened to cycle through my controller settings. I saw a display of “flow” when, of course, there was no water flow (a “fault” that did not shut the system down).

For the record, my 10-year old salt pool is controlled by Hayward ProLogic PL-PS4. So, I don’t know if other models or manufactures have the same setup or even if my unit was setup correctly. Who knows... my flow switch may have failed years ago!!

Here’s the rest of my story leading to the “enigma”:

Intending to bench test the electrical functionality of my OEM flow switch, I accidentally broke off the wire flush at top of the switch assembly… so couldn’t attach a meter.... no test.

I shorted together the 2 broken lead wires (makes the system run and produces chlorine as usual) while I went searching for a new flow switch.

Hayward OEM at Leslie’s for $249.99 or Amazon knockoff for $16.66? Reviews are good and bad for dozens of switches across many price points. Hayward says that only their OEM switch will work. Others claim that the cheap ones last for years. Amazon indicates that these switches are often returned as non-functional even when they subsequently test OK.

I did a minor exploration about reed switches and concluded that they generally are quite reliable. I surmised that the flow sensor issues may be more attributable to incorrect installations, plumbing obstructions, water flow, or mechanical problems.

Next, I plugged into my ProLogic a new (low-priced) flow switch; it didn’t work!

It’s just a switch, right? I did a bench test for continuity between the phone connector plug 2 center contacts. My multi-meter showed... open / then closed... as I squeezed the switch paddle back and forth. (As the magnet on the paddle nears the internal reed switch, it closes to complete the circuit; then it opens when the paddle springs back into its relaxed position.)

The switch works. But not in my system. What’s different? The wires? The plug??

It’s a phone plug…. probably RJ11-6P4C or RJ11-6P2C (6positions/4 contacts or 6positions/2contacts).

My old broken OEM assembly has 2 wires and its modular connector has just 2 contacts centrally located in the RJ11 plug.

Conversely, my new switch assembly has 4 wires and 4 contacts with only the 2 center wires connected to the flow switch … [Why do they use 15 feet of 4 wires when only 2 wires are needed!??]

Could this possibly make a difference? Both plugs have the same physical interface and both snap into the same female socket on the controller board.

For a test, I created a “jumper” cable by splicing a 2-wire cable to a 4-wire cable (using just the 2 center wires). The 2-contact end plugs into the ProLogic and the 4-wire flow switch plugs into the 4-contact end of the “jumper”. See attached photo of the work-around “jumper”.

My system is currently 100% functional for several days now.

Why this works baffles me! It’s my enigma! It doesn’t make any sense! Can anybody explain this?

In summary:

- 4-wire flow switch does not work in my ProLogic system except using a workaround phone plug conversion to 2 contacts (Don’t know about other controller models).

- My system will not shut down if the flow switch fails in closed position… not good! (Don’t know about other controller models).