Hi, I've been reading this forum with great interest. Very educational. Time to ask my own question.

I'm having a new IntelliCenter control system installed and realized this was also the time to replace my inefficient two-speed pool pump. (I had no idea how much better efficiency I would have!)

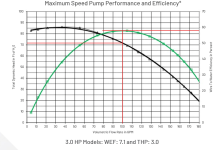

My installer is quoting the Sta-rite Intelliflo3 VSF at 1.5 HP, but I see a lot of recommendations from you folks that sizing up to a 3.0 HP pump run at a lower RPM will be much more efficient at the same flow rate.

I believe you, it makes sense. But here's my paranoid (chemical engineering) question. What are the risks doing a straight-up replacement in an existing system? If the pump runs full speed due to a software bug or a user error, what might break?

I've currently got 2" PVC from the pump to my cartridge filter (Pentair 160301) and (I think) mostly 1.5" PVC from the filter to the pool.

Thanks

I'm having a new IntelliCenter control system installed and realized this was also the time to replace my inefficient two-speed pool pump. (I had no idea how much better efficiency I would have!)

My installer is quoting the Sta-rite Intelliflo3 VSF at 1.5 HP, but I see a lot of recommendations from you folks that sizing up to a 3.0 HP pump run at a lower RPM will be much more efficient at the same flow rate.

I believe you, it makes sense. But here's my paranoid (chemical engineering) question. What are the risks doing a straight-up replacement in an existing system? If the pump runs full speed due to a software bug or a user error, what might break?

I've currently got 2" PVC from the pump to my cartridge filter (Pentair 160301) and (I think) mostly 1.5" PVC from the filter to the pool.

Thanks