We recently installed a new Rheem Raypac Crosswind 8550 electric heat pump. At the time of install the tech said we did not need to install an external bypass on the plumbing as there was an internal bypass already. My question how can we access that bypass and reduce the water flow? Since the install my floor pop ups are not working as before and from what I can figure out the flow to the heater is full force and needs to be reduced. Thanks

Raypac Crosswind 8550 internal bypass?

- Thread starter Zakos-dad

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jul 21, 2013

- 64,851

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

You cannot access the internal bypass. What it does is automatic and not a substitute for an external bypass.

A heat pump has small tubes that create a lot of restriction or “head” in the system that slows the water flow. Bypassing the heater when not in use can significantly increase water flow.

www.troublefreepool.com

www.troublefreepool.com

A heat pump has small tubes that create a lot of restriction or “head” in the system that slows the water flow. Bypassing the heater when not in use can significantly increase water flow.

Heater Bypass - Further Reading

At the time of install the tech said we did not need to install an external bypass on the plumbing as there was an internal bypass already.

How much flow does the in-floor cleaning system require?Since the install my floor pop ups are not working as before and from what I can figure out the flow to the heater is full force and needs to be reduced.

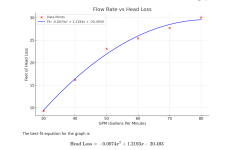

This Heat Pump has ridiculous Head Loss.

Y= -0.0074X^2 + 1.2194X - 20.4930.

Y = Head Loss in Feet.

X = GPM.

You need an external Bypass.

GPM.........Feet of Head Loss

30...................9.24

40...................16.17

50...................23.10

60...................25.41

70...................27.72

80...................30.03

Last edited:

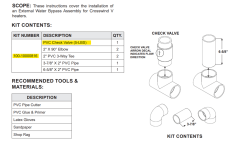

Bypass Assembly Kit (Part Number 100-10000816).

Deluxe models include a bypass assembly.

For standard models, the bypass assembly may be purchased as a kit separately.

Bypass Assembly kit should only be used if water flow to the unit will exceed 40 GPM (151 LPM) for 4550 models or 50 GPM (189 LPM) for 5550-8550 models.

www.eseasongear.com

www.eseasongear.com

AquaCal AutoPilot PLS2556 2556 Bypass Check Valve 5-lb

2" SLIP 5 lb bypass spring check valve, by pass, for pool heater heat pump installation, 5 lbs, 5#

If water flow rates through the heater will exceed 70-GPM, a spring-check bypass valve will be required.

Install AquaCal P.N.: 2556 5-LB bypass check valve, or bypass check valve equal to Del Industries PN: CO-0103.

See drawing, top of next page, for install location in site plumbing.

Deluxe models include a bypass assembly.

For standard models, the bypass assembly may be purchased as a kit separately.

Bypass Assembly kit should only be used if water flow to the unit will exceed 40 GPM (151 LPM) for 4550 models or 50 GPM (189 LPM) for 5550-8550 models.

AquaCal PLS2556 Bypass Check Valve 5-lb

AquaCal AutoPilot PLS2556 2556 Bypass Check Valve 5-lb

2" SLIP 5 lb bypass spring check valve, by pass, for pool heater heat pump installation, 5 lbs, 5#

If water flow rates through the heater will exceed 70-GPM, a spring-check bypass valve will be required.

Install AquaCal P.N.: 2556 5-LB bypass check valve, or bypass check valve equal to Del Industries PN: CO-0103.

See drawing, top of next page, for install location in site plumbing.

Last edited:

GPM.........Feet of Head Loss

30...................9.24

40...................16.17

50...................23.10

60...................25.41

70...................27.72

80...................30.03

Head Loss = -20.493 + 1.21935 * GPM - 0.00742 * GPM^2

www.wolframalpha.com

www.wolframalpha.com

30...................9.24

40...................16.17

50...................23.10

60...................25.41

70...................27.72

80...................30.03

Head Loss = -20.493 + 1.21935 * GPM - 0.00742 * GPM^2

y = -20.493 + 1.21935X - 0.00742X^2, y from 9 to 30 - Wolfram|Alpha

Wolfram|Alpha brings expert-level knowledge and capabilities to the broadest possible range of people—spanning all professions and education levels.

Last edited:

The Raypak part is expensive and all you really need is a 5 psi spring bypass.

5 psi = 11.5 feet of head loss.

A 5 psi spring check valve should give 32.84 GPM through the Heater.

www.wolframalpha.com

www.wolframalpha.com

www.inyopools.com

www.inyopools.com

Raypak Water Bypass for Crosswind V Heat Pump - 100-10000816. $281.34

www.inyopools.com

www.inyopools.com

www.inyopools.com

www.inyopools.com

DelCheck 5# Check Valve - CO0103. $25.97

www.eseasongear.com

www.eseasongear.com

s AquaCal PLS2556 Bypass Check Valve 5-lb

Item# AQC-PLS2556

List: $69.96

Sale: $27.94

5 psi = 11.5 feet of head loss.

A 5 psi spring check valve should give 32.84 GPM through the Heater.

11.55 = -20.493 + 1.21935X - 0.00742X^2 - Wolfram|Alpha

Wolfram|Alpha brings expert-level knowledge and capabilities to the broadest possible range of people—spanning all professions and education levels.

Raypak Water Bypass for Crosswind V Heat Pump - 100-10000816 - INYOPools.com

Raypak Water Bypass for Crosswind V Heat Pump - 100-10000816

Raypak Water Bypass for Crosswind V Heat Pump - 100-10000816. $281.34

Flo Control Valve, Check, 2 In, 5 Lb Spring (1095-20) - INYOPools.com

1095-20 - VALVE, CHECK, 2 IN, 5 LB SPRING (1095-20)

Del Ozone DelCheck 5# Check Valve - CO0103 - INYOPools.com

CO0103 - DelCheck 5# Check Valve

DelCheck 5# Check Valve - CO0103. $25.97

AquaCal PLS2556 Bypass Check Valve 5-lb

AquaCal PLS2556 Bypass Check Valve 5-lb

s AquaCal PLS2556 Bypass Check Valve 5-lb

Item# AQC-PLS2556

List: $69.96

Sale: $27.94

Last edited:

I was looking at the wrong model.

The 8550 has 9 psi head loss (20.79 feet) at 30 GPM.

That is a crazy amount of head loss.

You might need a 10 psi spring check valve bypass.

It is the same bypass.

Contact Raypak and ask them if the head loss data is accurate.

www.raypak.com

www.raypak.com

The problem is that the heat exchanger is a spiral titanium tube inside the larger tube.

This is not designed for the type of flow a pool has.

They need to increase the diameter of the inner and outer tubes.

This will not reduce the efficiency of the heat transfer.

It would actually improve the heat exchange efficiency.

It's the same mistake that they make with the gas heater and using multiple passes instead of a single pass.

Increased contact time seems like it should be better because the water gets hotter, but that reduces transfer efficiency.

For the hot side, you want to extract as much heat as possible, which means that the hot fluid gets cold.

For the colder pool water side, you want to minimize the temperature increase because there is always water moving through the system.

In other words, 100 gallons gaining 1 degree is more efficient than 10 gallons gaining 9.5 degrees.

It all goes into the main body of water either way.

What pump do you have?

If it is variable speed, what speed are you using?

What was the filter pressure before the heat pump was installed?

What is the filter pressure now?

Can you show the system>

Titanium Heat Exchanger for Pool Spa, Heat or Cool, Rheem/Raypak (H000369) 8450

The 8550 has 9 psi head loss (20.79 feet) at 30 GPM.

That is a crazy amount of head loss.

You might need a 10 psi spring check valve bypass.

It is the same bypass.

Contact Raypak and ask them if the head loss data is accurate.

Contact Us – Raypak

Raypak Pool & Spa, Residential and Commercial Hydronic Products -

The problem is that the heat exchanger is a spiral titanium tube inside the larger tube.

This is not designed for the type of flow a pool has.

They need to increase the diameter of the inner and outer tubes.

This will not reduce the efficiency of the heat transfer.

It would actually improve the heat exchange efficiency.

It's the same mistake that they make with the gas heater and using multiple passes instead of a single pass.

Increased contact time seems like it should be better because the water gets hotter, but that reduces transfer efficiency.

For the hot side, you want to extract as much heat as possible, which means that the hot fluid gets cold.

For the colder pool water side, you want to minimize the temperature increase because there is always water moving through the system.

In other words, 100 gallons gaining 1 degree is more efficient than 10 gallons gaining 9.5 degrees.

It all goes into the main body of water either way.

What pump do you have?

If it is variable speed, what speed are you using?

What was the filter pressure before the heat pump was installed?

What is the filter pressure now?

Can you show the system>

Titanium Heat Exchanger for Pool Spa, Heat or Cool, Rheem/Raypak (H000369) 8450 | eBay

ITEM IS BRAND NEW ONLY OPENED BOX TO SHOW EXACTLY WHAT YOU’RE PURCHASING WORKS ON RHEEM HEATPUMP POOL HEATERS NO RETURNS FOR ANY REASON AS ITEM IS BRAND NEW FROM FACTORY, ANY ISSUES JUST CONTACT ME I SHIP EXTREMELY FAST ALWAYS SAME DAY ANY QUESTIONS JUST ASK AND I WILL ANSWER ASAP!

www.ebay.com

Titanium Heat Exchanger for Pool Spa, Heat or Cool, Rheem/Raypak (H000369) 8450

Last edited:

The high head loss is due to water moving through a small titanium tube that is also spiraled.

In my opinion, they need to double the diameter of the titanium tube to provide better hydraulic efficiency.

Water flows through the inner tube and refrigeration flows between the outer & inner tube (refrigeration loop).

The temperature of refrigeration and water are different, so heat will transfer from one with high temperature to the other one.

The flow is mostly counter-flow.

If you have 100 lbs of water that has a 10 degree temp increase, that is 1,000 btu transferred.

Water In = 80 and water out = 90 degrees.

If you have 50 lb of water that has a 19 degree temp increase, then that is 950 btu transferred.

Water In = 80 and water out = 99 degrees.

People focus on the temp increase when they need to focus on the btu (heat) transferred.

blogandmeng.blogspot.com

blogandmeng.blogspot.com

The coaxial heat exchanger is designed as a "tube in tube" structure.

Usually the outer tube is made of steel/copper, and the inner tube can be titanium, copper, copper-nickel depending on the requirements of working condition.

For the inner tube is has many spiral grooves on the surface, which will enlarge the connection surface and get more heat transferred.

www.yojointernational.com

www.yojointernational.com

www.medallionenergy.com

www.medallionenergy.com

Coaxial coils are fairly simple in their construction.

The outside of the coil carries refrigerant, while the inside handles the water.

These coils are designed to counterflow the two mediums to exchange heat rapidly.

The inside of the coil is also rifled, creating a swirling effect that helps this process go further (see the diagram below).

hvacrschool.com

hvacrschool.com

In my opinion, they need to double the diameter of the titanium tube to provide better hydraulic efficiency.

Water flows through the inner tube and refrigeration flows between the outer & inner tube (refrigeration loop).

The temperature of refrigeration and water are different, so heat will transfer from one with high temperature to the other one.

The flow is mostly counter-flow.

If you have 100 lbs of water that has a 10 degree temp increase, that is 1,000 btu transferred.

Water In = 80 and water out = 90 degrees.

If you have 50 lb of water that has a 19 degree temp increase, then that is 950 btu transferred.

Water In = 80 and water out = 99 degrees.

People focus on the temp increase when they need to focus on the btu (heat) transferred.

How Does Coaxial Heat Exchanger Work?

What is a coaxial heat exchanger? A coaxial heat exchanger is a kind kind of tube heat exchanger, it is usually used as condenser or ev...

The coaxial heat exchanger is designed as a "tube in tube" structure.

Usually the outer tube is made of steel/copper, and the inner tube can be titanium, copper, copper-nickel depending on the requirements of working condition.

For the inner tube is has many spiral grooves on the surface, which will enlarge the connection surface and get more heat transferred.

What is a coaxial heat exchanger and how does it work?

A coaxial heat exchanger operates using a concentric tube design, with one tube fitting inside the other. The two tubes are separated by an air gap or filled with insulation to prevent heat transfer between them.

Understanding The Role Of A Pool Heat Pump Heat Exchanger

A pool heat pump heat exchanger distributes harvested heat, but exactly how it does that is what we explain in this post

www.medallionenergy.com

www.medallionenergy.com

Coaxial coils are fairly simple in their construction.

The outside of the coil carries refrigerant, while the inside handles the water.

These coils are designed to counterflow the two mediums to exchange heat rapidly.

The inside of the coil is also rifled, creating a swirling effect that helps this process go further (see the diagram below).

Introduction to Pool Heat Pumps

A quick and simple guide to the basics of operation, method of heat exchange, and safety features found in air-to-water pool heat pumps.

The Raypak Head Loss seems excessive compared to other manufacturers.

9 psi (20.79 feet) at 30 gpm does not seem right.

Also, the pressure does not increase in the expected way.

At 60 gpm, the expected pressure should be 4 times as high, but it is only about 1.22 times higher.

At 80 gpm, the expected pressure should be about 7 times higher, but it is only about 1.44 times higher.

Check with Raypak to verify the head loss graph and charts.

Get the 5 lb bypass (5 psi spring) to improve efficiency.

heatpumpsuppliers.com

heatpumpsuppliers.com

9 psi (20.79 feet) at 30 gpm does not seem right.

Also, the pressure does not increase in the expected way.

At 60 gpm, the expected pressure should be 4 times as high, but it is only about 1.22 times higher.

At 80 gpm, the expected pressure should be about 7 times higher, but it is only about 1.44 times higher.

Check with Raypak to verify the head loss graph and charts.

Get the 5 lb bypass (5 psi spring) to improve efficiency.

Patriot Heat Pumps | Pool Heat Pumps Suppliers

Last edited:

The Ultratemp does have a check-Valve bypass (Green Dot).

39 R172305 Water Bypass Check Valve.

This is a Pentair Water Bypass Check Valve, 1.5 inch socket, with a 12 pound spring for UltraTemp Heat Pumps.

This check valve is also designed for the Thermaflo Heat Pumps.

www.poolweb.com

www.poolweb.com

39 R172305 Water Bypass Check Valve.

This is a Pentair Water Bypass Check Valve, 1.5 inch socket, with a 12 pound spring for UltraTemp Heat Pumps.

This check valve is also designed for the Thermaflo Heat Pumps.

R172305 - UltraTemp Water Bypass Check Valve - 1.5 Inch Socket - Pentair

This is a Pentair Water Bypass Check Valve, 1.5 inch socket, with a 12 pound spring for UltraTemp Heat Pumps. This check valve is also designed for the Thermaflo Heat Pumps.

www.poolweb.com

www.poolweb.com