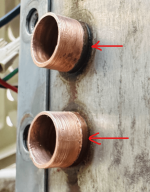

Pool/spa heater in our salt pool is a over 9 years old and I just took the manifold off for just the second time in it's life (thermostat/internal bypass replacement), but I see that the bottom left tube end is quite corroded. I feel like there's enough left to clean up and put a new o-ring on, but wondering how much longer you folks think this will hang on? One or two years? Heater is only used for the spa but is piped in for both (no bypass).

Thinking I should start saving for a new heater, don't think I'd be inclined to replace the tube sheet on a >10yr old heater. So far the only repairs have been an internal bypass at around 4yrs old, and a flue sensor last year, so hardly any maintenance needed to date. However, things seem pretty rode hard in there so I would just replace the whole thing.

Thoughts from the community? Am I overthinking it?

Will look to see if I have pictures from the first internal bypass replacement.

Thanks,

Tony

Equipment: 25k gal inground pool/spa, IC40 salt cell, Intelliflow VS, De filter, Mastertemp 400

Thinking I should start saving for a new heater, don't think I'd be inclined to replace the tube sheet on a >10yr old heater. So far the only repairs have been an internal bypass at around 4yrs old, and a flue sensor last year, so hardly any maintenance needed to date. However, things seem pretty rode hard in there so I would just replace the whole thing.

Thoughts from the community? Am I overthinking it?

Will look to see if I have pictures from the first internal bypass replacement.

Thanks,

Tony

Equipment: 25k gal inground pool/spa, IC40 salt cell, Intelliflow VS, De filter, Mastertemp 400

:max_bytes(150000):strip_icc():format(webp)/US0001-Lincoln-Wheat-Copper-Color-Scale-56a177e03df78cf7726af244.jpg)