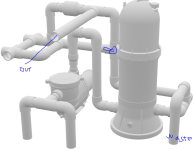

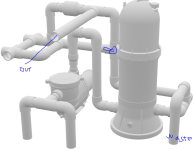

Okay, it's go time, new Intelliflo 3hp pump (different size than my whisperflo) and new Aquastar filter. Will be replacing 20+ year old DE filter. New filter has inlet on left, outlet on right, and drain in front. Got lucky, it's very similar to the diagram.

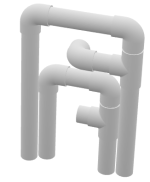

I have blue painters tape on my garage floor to represent my equipment pad, not very big. Roughly 24 deep by 36 wide. Heater not included in that, it's off to the left. I have a few inches between the pad and the house, so the 'overhang' on the pump is okay.

Issue 1

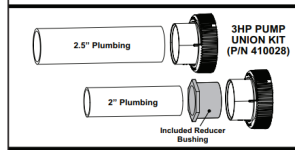

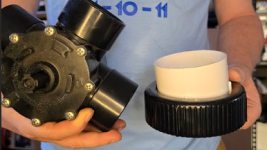

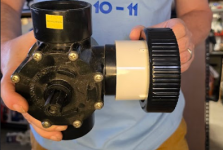

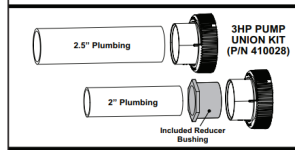

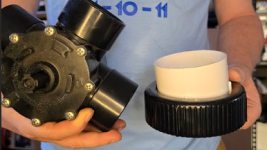

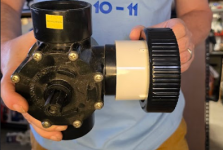

The Jandy diverter valve, pulling from Pool/Spa, it would fit directly into the large opening for the pump, but of course that'd be a mistake. Ruins both. If I glue the Jandy directly into the union, it's very close, but still removable. Also, it doesn't reduce flow down to 2". Would that work? Images below.

Okay, on to question 2.

I have backwash plumbing in the ground near the filter. New filter doesn't backwash, since it's cartridge. I heard you don't really want to just open the drain plug on the filter for use in this case, as it could damage a filter.

If I am replumbing, should I consider putting in a tee/valve for a way to drain the pool if needed? If so, should that be after the filter or before? Would it be better to have a diverter, or 2 ball valves? (one for the to-heater that stays open, and one for the to-hose or to-backwashplumbing that stays off) Note - I have a submersible pump, so I can always use that if needed. Should I just stick with that?

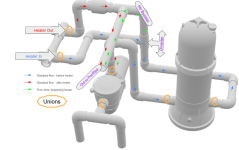

Finally, the heater bypass. Can't tell completely by the diagram, the diverter valve would be on the vertical up/down pipe after the filter. Does that layout look right? Other than right at the connections to the pump, heater, and filter, are there any recommended spots for unions or ball valves? Going to do this all over the next day or two hopefully.

*Thanks for the other thread on pvc cutting. I never thought to use a circular saw.

I have blue painters tape on my garage floor to represent my equipment pad, not very big. Roughly 24 deep by 36 wide. Heater not included in that, it's off to the left. I have a few inches between the pad and the house, so the 'overhang' on the pump is okay.

Issue 1

The Jandy diverter valve, pulling from Pool/Spa, it would fit directly into the large opening for the pump, but of course that'd be a mistake. Ruins both. If I glue the Jandy directly into the union, it's very close, but still removable. Also, it doesn't reduce flow down to 2". Would that work? Images below.

Okay, on to question 2.

I have backwash plumbing in the ground near the filter. New filter doesn't backwash, since it's cartridge. I heard you don't really want to just open the drain plug on the filter for use in this case, as it could damage a filter.

If I am replumbing, should I consider putting in a tee/valve for a way to drain the pool if needed? If so, should that be after the filter or before? Would it be better to have a diverter, or 2 ball valves? (one for the to-heater that stays open, and one for the to-hose or to-backwashplumbing that stays off) Note - I have a submersible pump, so I can always use that if needed. Should I just stick with that?

Finally, the heater bypass. Can't tell completely by the diagram, the diverter valve would be on the vertical up/down pipe after the filter. Does that layout look right? Other than right at the connections to the pump, heater, and filter, are there any recommended spots for unions or ball valves? Going to do this all over the next day or two hopefully.

*Thanks for the other thread on pvc cutting. I never thought to use a circular saw.