I'm in WV for location context. My pool build started July 3rd and I'm currently sitting with a gunite shell and no plaster. From what I've read about the application:

All materials and effected areas should remain above 50°F / 10°C (fifty degrees Fahrenheit / ten degrees Celsius) or below 100°F / 38°C (100 degrees Fahrenheit / 38 degrees Celsius) 24-hours prior and 72-hours after placement.

Diamond Brite Plaster - Temperature

- Thread starter whiskaz

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Do not allow them to plaster now  They need to find a dry place to store the bags inside until the temps will be and stay within the proper window.

They need to find a dry place to store the bags inside until the temps will be and stay within the proper window.

Thank you for the feedback!

I will be contacting a Diamond Brite rep tomorrow to get feedback "straight from horse's mouth" since I'm sure the builder is going to push back.

Hopefully the shell is ok being exposed to the elements until spring. I doubt we will get a 4-day window, or even close, with temps above 50.

I will be contacting a Diamond Brite rep tomorrow to get feedback "straight from horse's mouth" since I'm sure the builder is going to push back.

Hopefully the shell is ok being exposed to the elements until spring. I doubt we will get a 4-day window, or even close, with temps above 50.

- Jul 21, 2013

- 64,776

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

All materials and effected [sic] (affected) areas should remain above 50°F (10°C) or below 100°F (38°C) 24 hrs. prior and 72 hrs after placement.

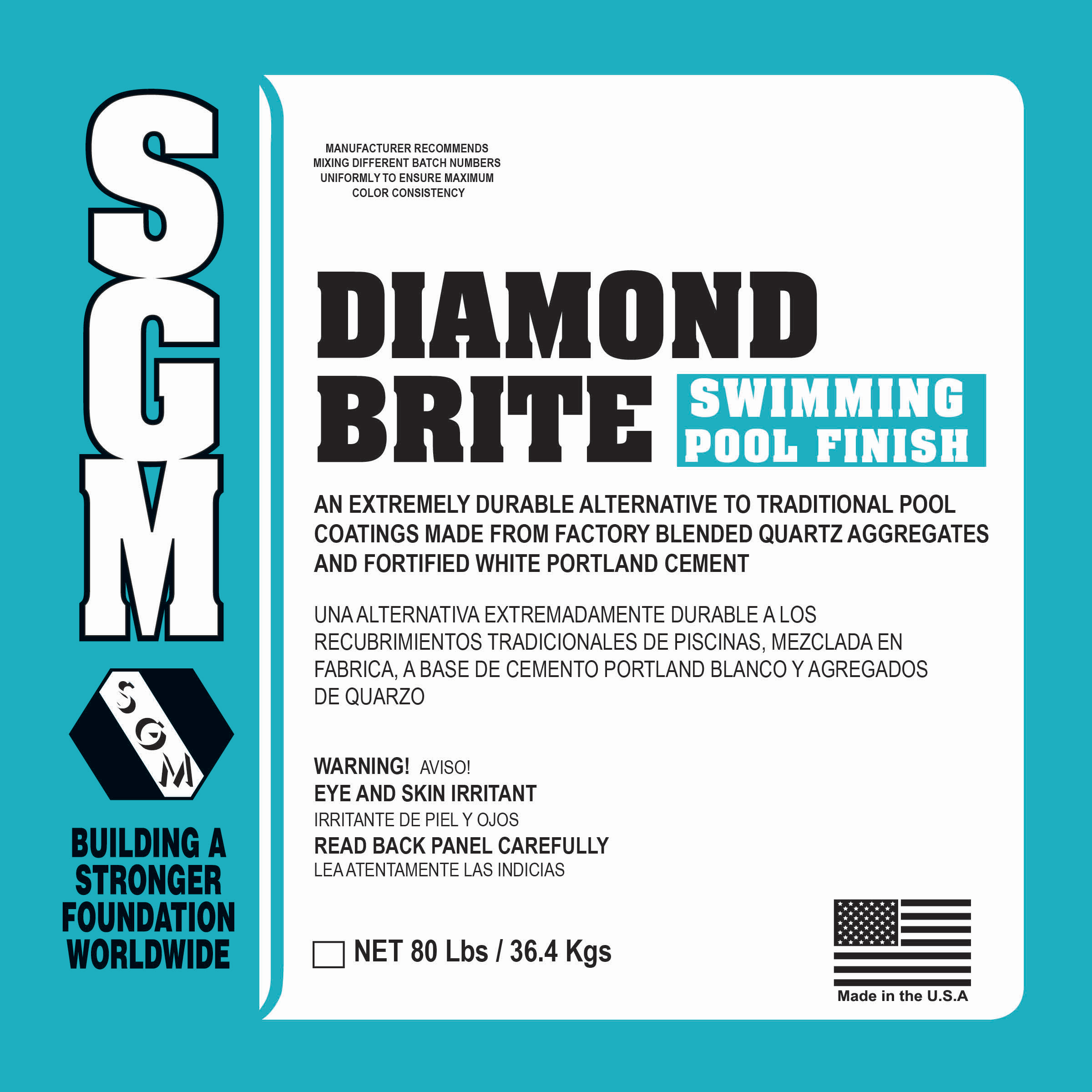

Diamond Brite Swimming Pool Plaster

diamondbrite.us

diamondbrite.us

Diamond Brite® - SGM, Inc.

Diamond Brite® finishes are blends of selected quartz aggregates and fortified white Portland cement ideal for new or re-finished swimming pools. Diamond Brite® finishes are factory blended to provide the pool owner with an extremely durable and attractive alternative to traditional pool...

www.sgm.cc

www.sgm.cc

Product Details

Info

Colors

Technical

Warranty

SGM Inc. warrants this product will perform in accordance with its intended use for a period of one year from the date of manufacture. Any claim for defective products must be submitted in writing to SGM Inc. and samples of the defect must be provided. SGM Inc.‘s sole obligation will be to replace any product determined to be defective by SGM Inc. EXCEPT AS PROVIDED HEREIN, SGM INC. MAKES NO OTHER REPRESENTATION OR WARRANTY OF ANY KIND, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE. IN NO EVENT SHALL SGM INC. BE LIABLE FOR DAMAGES OF ANY KIND OR NATURE, WHETHER ARISING BY CONTRACT, TORT OR OTHERWISE. SGM INC.’S SOLE OBLIGATION WILL BE TO REPLACE ANY PRODUCT DETERMINED BY SGM INC. TO BE DEFECTIVE. Customers may acquire an extended 5-year commercial or 10-year residential warranty. Please visit our Warranty page.

Warranty - SGM, Inc.

Register your Warranty Thank you for choosing SGM Swimming Pool, Spa and Deck finishes. We hope you will begin to enjoy your new pool or deck project. In developing SGM finishes, we made ease of maintenance a top priority as a sign of our commitment to achieve the highest quality standards. SGM...

www.sgm.cc

www.sgm.cc

Plaster Installation and Maintenance - Further Reading

The Best Plaster Pool Startup

Additional clarifications on the Bicarb (or Positive CSI) Startup. THE BEST PLASTER POOL START UP How a startup program deals with and prevents the detrimental process of “plaster dust” forming in newly plaster pools is the key in helping to preserve a quality plaster finish that will last 20+...

How to Ensure a Quality Pool Plastering Job

For pool owners, pool builders, remodeling companies, and pool plasterers that want the best chance to obtain a quality and discoloration-free pool plaster job (including white, color, and quartz aggregate pools), the link below is to an article in WaterShapes (a pool industry publication) that...

Ten Guidelines for Quality Pool Plaster

There are proper steps to follow for the making of durable pool plaster. There are also improper practices that can lead to early deterioration or discoloration. Following is a ten-point checklist that will help achieve a lasting and discoloration free plaster. 1. The best cement/aggregate...

Attachments

Last edited:

Glad to hear that - my biggest concern was ground water/freeze/thaw wreaking havoc.Shell is just concrete that can sit outside for years.

Now the fight begins to get my final payment refunded until the job is completed...

For the warranty to be valid, the installation instructions need to be followed unless you can get the manufacturer to give written permission to apply in conditions outside of the written installation instructions.

Now the fight begins to get my final payment refunded until the job is completed...

- Jul 21, 2013

- 64,776

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Show us pictures of the shell and area.

If you have groundwater around it then talk to your PB about drilling a hole or two in the bottom to release any pressure. The hole would be filled with hydraulic cement once they are ready to plaster.

If you have groundwater around it then talk to your PB about drilling a hole or two in the bottom to release any pressure. The hole would be filled with hydraulic cement once they are ready to plaster.

Yea - I know. I keep learning hard lessons that should be obvious. Per the contract, final payment was due the DAY BEFORE plaster application. I should have questioned/not agreed to this from the get-go, but alas, here we are and I made good on the contract - they did not.

Show us pictures of the shell and area.

If you have groundwater around it then talk to your PB about drilling a hole or two in the bottom to release any pressure. The hole would be filled with hydraulic cement once they are ready to plaster.

Pics attached, including the truck they left on site... the bed of which is filling up with water (never bothered to check it out). The plaster is sitting on a pallet but...yea... Couldn't find a date on the stuff, didn't want to remove the plastic.

According to the PB - "there is no risk because there is a hydrostatic valve in the bottom of the pool to relieve any pressure". There's a couple of drains down there...all but 1 of the 4 holes (2 in each) are capped off. Not sure if the other should be or not. I kind of assumed those are just plumbing though.Show us pictures of the shell and area.

If you have groundwater around it then talk to your PB about drilling a hole or two in the bottom to release any pressure. The hole would be filled with hydraulic cement once they are ready to plaster.

- Aug 20, 2020

- 7,716

- Pool Size

- 27000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

I’ve seen instances of the plaster folks tenting the area and having some heaters to keep it within temp. Maybe they can do that here.

Kinda looks like there were some cracks in the shell that they patched?

Kinda looks like there were some cracks in the shell that they patched?

The surrounding ground looks lower, which gives you some protection against floating the shell, but there is still some risk during a heavy rain if the water table gets high quickly.

I know, right? They are about 3 hours away (the closest PB that worked with gunite). The plaster company is a 3rd party that they hire - they simply provide the materials to them (which seems odd to me as well). I do believe they intended to perform the plaster application shortly after dropping the material off but 1) one of the lights they provided was too short for my electrician to pull - they were supposed to deliver a longer one with the plaster material - they didn't - then they failed to overnight it. Once it finally arrived, the plaster company had "equipment issues" and now here we are, into bad weather.It seems odd to me that they left a truck in your driveway.

I'm not sure the truck + plaster material is worth what my final payment was but I do have the keys...

Yea - when the PB came back to prep the shell for plaster, they had to fill some cracks - cracks that I don't recall seeing prior to their arrival so I'm thinking they may have created some decent sized crevices while pressure washing. Unfortunately I didn't grab photos of that before they had them patched with hydraulic cement.I’ve seen instances of the plaster folks tenting the area and having some heaters to keep it within temp. Maybe they can do that here.

Kinda looks like there were some cracks in the shell that they patched?

Yea - I think the grading is good around it (we brought in a LOT of dirt to build up the area on the backside of the pool. I think it will be fine but also want to CYA (somehow) in the event that the worst happens while waiting for the pool to have water in it...The surrounding ground looks lower, which gives you some protection against floating the shell, but there is still some risk during a heavy rain if the water table gets high quickly.

The light has nothing to do with the plaster application.I do believe they intended to perform the plaster application shortly after dropping the material off but 1) one of the lights they provided was too short for my electrician to pull - they were supposed to deliver a longer one with the plaster material - they didn't - then they failed to overnight it. Once it finally arrived, the plaster company had "equipment issues" and now here we are, into bad weather.

The light can be installed at any time after the plaster is installed even if the pool is full.

Check to see if the tile is level using a piece of vinyl tubing full of water.

The tubing can be small diameter, but not too small diameter or you will get capillary action that interferes with the test.

Put one end of the tubing at one end of the pool and the other end of the tubing at the other end of the pool and see if the water level is the sale at the bottom of the tile and at the coping.

The tubing can be small diameter, but not too small diameter or you will get capillary action that interferes with the test.

Put one end of the tubing at one end of the pool and the other end of the tubing at the other end of the pool and see if the water level is the sale at the bottom of the tile and at the coping.

Last edited:

Ah - ok - good to know. They've been terrible about scheduling and communication from the get go. I have a timeline dating back to March. The table top pictured caused a slight delay. I was responsible for providing that and having it installed. The PB knew the size I wanted to do and supposedly spec'd a column large enough. Well, it needed extra support so a steel bracket was fabricated. Beyond that, they never bothered to communicate when the best time to install the table top would even be. That caused the slightest of delays as the fabricator was incredibly fast with their turnaround. I sometimes waited days/weeks between work happening and "any updates?" ever since they broke ground in July. We've had incredibly dry, warm weather throughout. It never should have gotten this far.The light has nothing to do with the plaster application.

The light can be installed at any time after the plaster is installed even if the pool is full.

Oh man... I don't know if I want to KNOW about that at this point! I'm already worried the table top is going to be very close to the waterline.Check to see if the tile is level using a piece of vinyl tubing full of water.

Put one end of the tubing at one end of the pool and the other end of the tubing at the other end of the pool and see if the water level is the sale at the bottom of the tile and at the coping.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.