I always hated the design of the wedding cake support arm that goes from the top step upright and then screws into your deck. It has to set on top of your top rail and then you have to put a block or something on your deck to make up the difference in height so you could screw in into place.

The first 2 photos shows what i had, and i did not want to put a block of wood under to secure it to make up the difference in height.

My solution (proposed by another member) was to scribe out the profile of the top rail and cut the support arm to match so it would fit over the top rail and rest flush on the deck.

I really loved the clean look of this solution but it really lost its strength cutting so much out of it. I had 2 support arms and they lasted a total of 3 seasons.

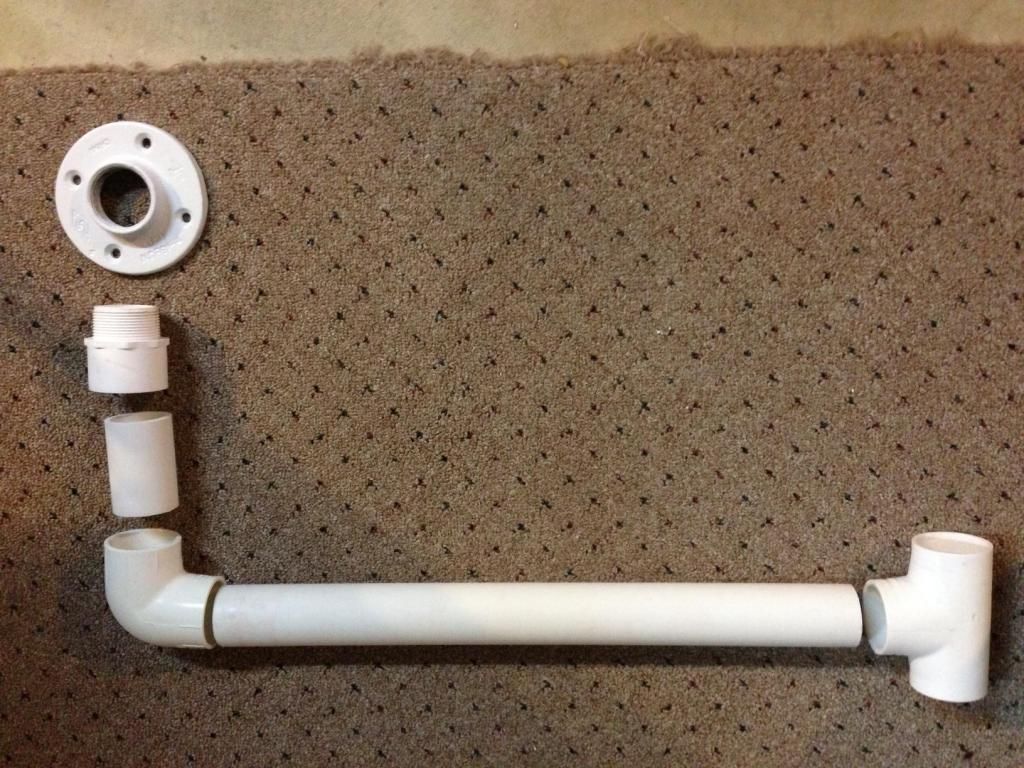

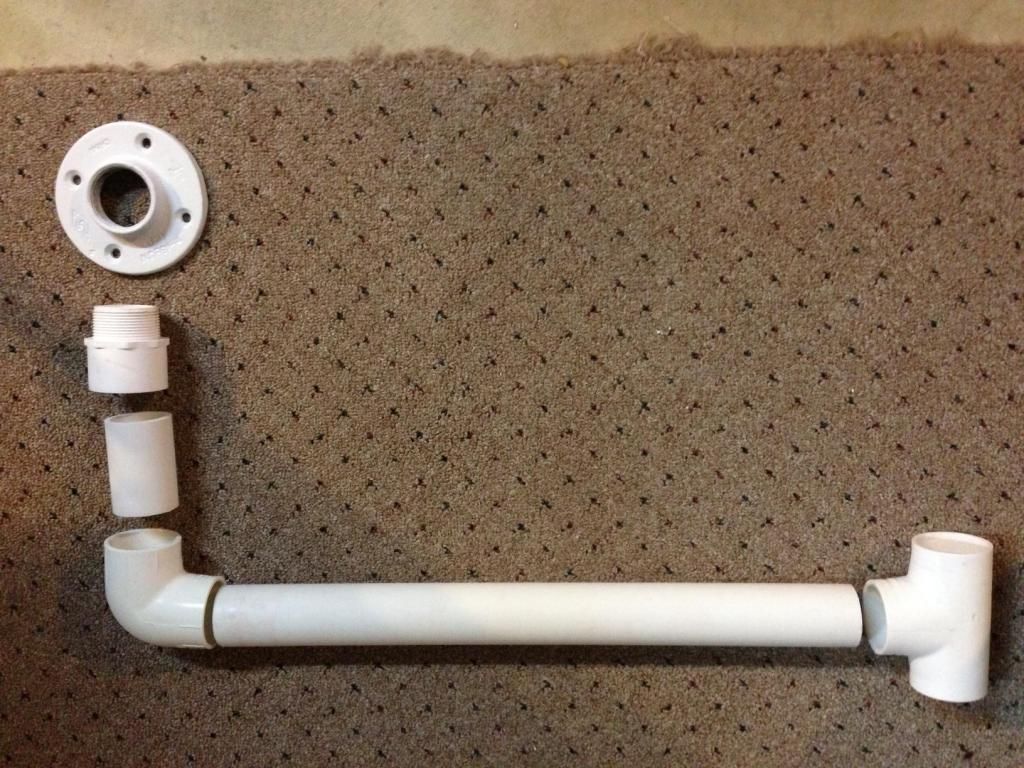

Since i had no more factory support arms i decided to go with regular PVC pipes, elbows, connectors and hold downs.

I believe this approach will work with a lot of different styles of steps for anyone's custom application.

I had to grind the inside of the T coupling so it could slide down my existing stair upright pole, but after that it was pretty much just cutting to your desired lengths and gluing together.

I did remove any lettering that was stamped on the PVC pipes then i sanded them smoother and then applied 4 coats of plastic high gloss white paint.

Below are the results.

I did add one more coupling to one end of the finished support prior to installation for a little extra strength at the stress point.

I like the results and it really is much stronger than the original. All of my material was 1 1/2" pvc piping.

Hopefully this will help another member who may have the same situation.

The first 2 photos shows what i had, and i did not want to put a block of wood under to secure it to make up the difference in height.

My solution (proposed by another member) was to scribe out the profile of the top rail and cut the support arm to match so it would fit over the top rail and rest flush on the deck.

I really loved the clean look of this solution but it really lost its strength cutting so much out of it. I had 2 support arms and they lasted a total of 3 seasons.

Since i had no more factory support arms i decided to go with regular PVC pipes, elbows, connectors and hold downs.

I believe this approach will work with a lot of different styles of steps for anyone's custom application.

I had to grind the inside of the T coupling so it could slide down my existing stair upright pole, but after that it was pretty much just cutting to your desired lengths and gluing together.

I did remove any lettering that was stamped on the PVC pipes then i sanded them smoother and then applied 4 coats of plastic high gloss white paint.

Below are the results.

I did add one more coupling to one end of the finished support prior to installation for a little extra strength at the stress point.

I like the results and it really is much stronger than the original. All of my material was 1 1/2" pvc piping.

Hopefully this will help another member who may have the same situation.