1.

I think it's possible that sun on the roof-top temperature sensor could signal the solar controller to start heating before the sun actually heated up the water leftover in the array. Which means when the pump fires up, instead of pushing a "new" batch of pool water onto the roof and displacing the air that filled the array the day before, it'd be pumping "leftover roof water" right into your pool that has been cooling off all night, certainly a lot colder than the pool water. I can't say how that would affect the overall heating efficiency that day, but it certainly is bad form.

2.

You shouldn't have to remember to drain your array every time a freeze is imminent, or even remotely possible. What if you aren't even home? Or forget? Or otherwise just can't? Unless your arrays are below the pool's water level, plumbing them so that they drain themselves automatically each day (regardless of which State they live in), is so easy to do as to make it pretty much ridiculous not to. (IMO)

3.

There may be other reasons why it's good practice that the array(s) are emptied each night that I'm not thinking of (

@mas985?).

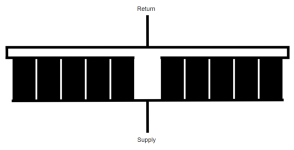

Are you saying the source water of your array enters the array into the top manifold (the highest point of the array), and then exits the array from the bottom manifold (the lowest point)? I can't say exactly why that is bad, but as far as I know that is never done, so there must be a good reason for it.

@mas985? That can't be right. I think that setup could easily trap air somewhere in the array, and any air at all in the tubing is a loss of heating efficiency.

And while it's hard to say for sure without pics, if there is a way to incorrectly put water into the top of your array and take it out at the bottom, then certainly there must be a way to do it correctly. Maybe those pipes can't now be crossed up on the roof, but certainly at some point lower!

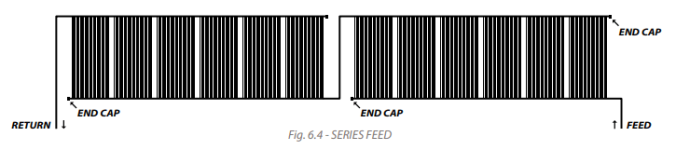

Pardon for saying, but solar installers that don't know enough to feed an array from the low point, while also running arrays end-to-end, sure sound to me like they have no idea what they're doing, or worse, just don't care enough to do it correctly. So odd.

Regarding the tilt I described, even the solar company that sold me my array didn't understand that concept, and said they never do that. So it doesn't surprise me that it's not in the Heliocol installation guide. But if you watched the animations I linked, it sure seems pretty clear to me why this is pretty important.

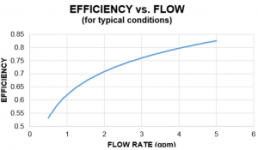

A solar heating system is not going to heat your pool to excess. It barely can make it a little warmer. There is no wiggle room, nor abundant amount of extra heat to be wasted. You need every therm. This is the one point where

@mas985 and I are not 100% in sync. He sometimes states plumbing and flow rate scenarios, that might short you a small percentage of heating efficiency, as no big deal, something that would not be noticeable to the user. And I can't argue that's not true. But I'm running my pump and I paid for the panels, so if I can just as easily eke out a little more efficiency as simply as not, then why wouldn't I?

Full disclosure: I have PV solar so pay nothing for pump runtime or extra flow rate.

@mas985's MO (if I may) is addressing the concern of heating efficiency vs the cost of the electrical energy to provide that heating. Since I have no cost of electrical energy, that makes me lean on the side of heating efficiency. As long as you understand the principals, then you can make up your own mind about that.

Mark, pardon me if I'm incorrectly interpreting your thoughts about such things.